Why Choose Crimped Wire Mesh for Edging?

Aug. 06, 2024

Why choose crimped wire mesh for edging? Crimped wire mesh offers unparalleled durability, flexibility, and aesthetic appeal for edging applications. Delving deeper into these advantages will demonstrate why it stands out as a superior choice for both functional and decorative purposes.

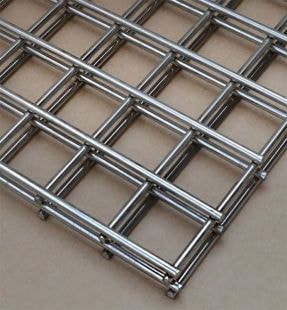

## Understanding Crimped Wire Mesh.

Crimped wire mesh consists of wires that are pre-crimped before weaving, which means the wires are bent in precise intervals. This process ensures a tight and secure weave that maintains its structure even under significant stress. Let's explore the key benefits it offers.

### Durability.

One of the primary reasons crimped wire mesh is highly recommended for edging is its exceptional durability. The pre-crimping process increases the mesh's strength, making it resilient to wear and tear. Whether used in industrial settings, garden borders, or architectural frameworks, this type of mesh withstands environmental pressures, temperature changes, and mechanical impacts better than plain woven mesh.

### Flexibility.

Crimped wire mesh is also highly flexible, accommodating various design needs and applications. It can be manufactured with different wire gauges and aperture sizes, providing versatility in its use. This flexibility allows for custom solutions that are tailored to specific projects, making it an excellent choice for both large-scale industrial uses and intricate decorative tasks.

## The Aesthetic Appeal.

### Visual Versatility.

Featured content:Everything You Need to Know About 3D Welded Wire Fence

Ultimate Guide to V Mesh Security Fencing

How to Choose 3D Wire Mesh Fence: A Comprehensive Guide

10 Questions You Should Know about Twin Wire Mesh Fencing

Expanded Mesh vs. Perforated Metal: Which Should You ...

10 Questions You Should to Know about Diamond Mesh Metal Lath

Key Questions to Ask When Ordering 358 Security Fence

Another significant advantage of crimped wire mesh is its aesthetic versatility. Its intricate patterns add an element of sophistication to any project, be it interior design, exterior architecture, or simple garden edging. The mesh’s appearance can be customized to blend with or stand out from its surroundings, offering a broad range of visual possibilities.

## Practical Applications.

### Industrial Uses.

In industrial settings, crimped wire mesh is often employed for sieving and filtering, thanks to its ability to maintain its shape under heavy loads. This durability is crucial for continuous, long-term use in demanding environments, ensuring efficiency and productivity.

### Decorative Purposes.

For decorative purposes, such as fencing and garden edging, crimped wire mesh provides a blend of form and function. Its strength ensures lasting use, while its visual appeal enhances the beauty of the landscaped areas. Moreover, it can be coated with various finishes, such as galvanized or PVC, to improve its resistance to corrosion and to match aesthetic preferences.

## Conclusion.

In summary, crimped wire mesh is an ideal choice for edging due to its durability, flexibility, and aesthetic potential. Its pre-crimped design ensures robust performance in various settings, from heavy industrial applications to delicate decorative projects. Whether you're aiming for practicality or visual impact, crimped wire mesh delivers on all fronts, making it a preferred option for diverse needs.

If you want to learn more, please visit our website Crimped wire mesh for garden edging, Quarry Wire Mesh pieces wholesale, square flat top locked woven wire screen factory.

Featured content:The Benefits Of Using 316 Filler Wire

Custom fence panels

What is Expanded Metal Mesh and How is It Used?

Lath

Sintered Metal Filter Manufacturer

Info Shale Shaker Screen - Aipu

Multil Layer Agriculture Planting Seedbed Flood and Drain ...

94

0

0

All Comments (0)

Previous: 10 Questions You Should to Know About Crimped Wire Mesh for Rooftop Gardens

Next: Revolutionizing Coal Mining: Is Quarry Screen Mesh the Key?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments