Water Bottle ODM/OEM Manufacturer

Jul. 15, 2024

Water Bottle ODM/OEM Manufacturer

The OEM supplier's product is based on the design provided by the buyer. In other words, they only produce what the buyer needs. They create designs and manufacture products in-house. Products from ODM manufacturers are often referred to as white-label products. The following are the main differences between the two:

Are you interested in learning more about OEM pet plastic bottle? Contact us today to secure an expert consultation!

What is OEM?

In the supply chain, OEM stands for Original Equipment Manufacturing, which is a type of outsourced manufacturing or contract. OEM factories create products according to customers' designs and specifications. After opting for this type of manufacturing, you must provide the manufacturer with a product specification sheet and product design.

You can customize a manufacturer's product or choose to design a new one. Additionally, most OEM projects will require manufacturers to create custom tooling or purchase new tooling and equipment, especially if demand is high. In other words, you have to pay the manufacturer up front.

The buyer owns the intellectual property because he designed the product and created the spec sheet. Also, the buyer may have production rights, since he will pay for the molds and tooling. This type of contract may prevent the manufacturer from using molds and tooling for other customers.

Advantages and disadvantages of OEM

OEM has its advantages and disadvantages. Here are the advantages and disadvantages of this option.

Advantage:

1. Most manufacturers have OEM factories. This means that this is the easiest type of manufacturer to find.

2. OEM allows you to make the best products for the target market.

3. If you have appropriate protection and contracts, you will have intellectual property rights.

4. You will introduce your own products to the market.

Shortcoming:

The buyer pays for tools and molds, which may be very expensive depending on the nature of the customization.

The creation of stencils and new stencils may take a long time.

The buyer must propose the design and specification table before starting production. In addition, the buyer must ensure that the format of the specification sheet is good so that the manufacturer has time to understand it.

What is ODM?

ODM represents the original design manufacturer in the supply chain. This means that the manufacturer must manufacture products according to the buyer's design, but based on existing products. After selecting this type of manufacturing, you will purchase the items produced by the factory. The only thing you can change or design is the brand and packaging.

In most cases, the buyer will not change the packaging or brand. They sell products according to the products provided by the factory. However, some buyers may require some appearance changes, such as size, shape, color, and logo addition. The difference between ODM and OEM manufacturing is the customized quantity completed, but in order to simplify everything, ODM is more about marketing existing products.

The biggest problem of ODM manufacturing involves the owner of intellectual property and product design, including customization. As we have said, the factory works on the design or part of the whole design, so it has intellectual property rights. The buyer will own the brand copyright. This creates a big problem because some buyers think that the manufacturer may sell the product.

Advantages and disadvantages of ODM

Like OEM, ODM has its advantages and disadvantages. Here are the expected advantages and disadvantages.

Advantage:

Product development takes a little time. The manufacturer will ship the product to you in a few days so that you can start retailing.

Most manufacturers offer little customized content.

There are no additional costs associated with molds and tools.

Shortcoming:

You can only accept products from suppliers. There are no custom options.

Your main competitors will have access to the products you plan to sell.

You will not get intellectual property protection.

Suppliers may infringe on others' intellectual property rights.

Conclusion

In short, if you want to build a water bottle brand and use the existing water bottle models on the market to own your own private brand, you need an ODM manufacturer.

As one of the best water bottle manufacturing companies in china, Everich & Kingvac is dedicated to the R&D, design, and manufacture of various outdoor drinkware products, they are 100% food-safe grade, comply with European and American food safety standards, we have rich experience in OEM and ODM services, and our R&D team is able to form more than 450 pieces of new product design solutions every year.

With our outstanding R&D and design capabilities, good product quality and cost performance, and fast product delivery, we have gained recognition and established more stable relationships with international brand owners and large supermarkets. We have also helped many startups grow together and help them profit from their projects. Please contact us for bulk orders of water bottles.

Everich ' Water Bottle ODM ManufacturerThe things to know about plastic bottles in pharmaceutical ...

2. Some types of plastics used in pharmaceutical packaging production and their advantages

1. Some issues to consider in pharmaceutical packaging production

Plastic bottles are increasingly being used in various manufacturing industries in general and the pharmaceutical industry in particular. Just like many other industries, the pharmaceutical industry needs to pay special attention to hygiene and safety issues to ensure the quality of the medication inside while maintaining the aesthetic appeal of the packaging. To produce pharmaceutical bottles, we need to consider issues such as the type of plastic, quality standards, protective features, and learn about some important considerations in pharmaceutical bottle production through the article below.

1. Some issues to consider in pharmaceutical packaging production

Plastic bottles are widely used in pharmaceutical packaging production. Here are some things to know about plastic bottles in pharmaceutical packaging production:

For more personalised perfume bottlesinformation, please contact us. We will provide professional answers.

Featured content:Cell Culture Basics: Equipment, Fundamentals and Protocols

The Difference Between Thermoforming and Cold Forming

Non-Wet Strength Metallized Paper: A Versatile Solution for Various Applications

Glass Bottles for Pharmaceutical Use: Ensuring Safety and Quality

Aluminium Flip Off Seal: Ensuring Product Integrity and Security

Choosing the Right Handheld Inkjet Printer: Features and Considerations

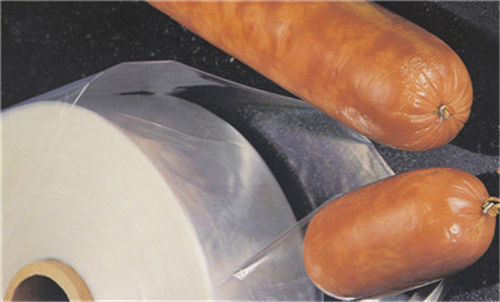

Which industries benefit the most from using shrink film for packaging and product protection?

Types of plastics used: Plastic bottles are produced from various types of plastics such as PET, PP, PE, PVC, etc. Depending on the product requirements, the appropriate type of plastic will be used to manufacture the bottles.

- Quality standards:

The production of plastic bottles for pharmaceutical packaging must meet strict quality standards, including transparency, durability, elasticity, hardness, thickness, and waterproofing ability.

- Quality control:

The process of producing plastic bottles in pharmaceutical packaging must be closely monitored to ensure product quality. Quality control parameters include temperature and pressure during production, transparency, thickness, and waterproofing ability of the bottles.

- Hygiene and safety:

Pharmaceutical bottle manufacturing facilities must ensure food hygiene and safety. Requirements include clean rooms, isolation, and ensuring that the production process is carried out in a safe environment.

- Customization of sizes:

Plastic bottles can be manufactured in various sizes to meet the product's needs. These sizes include the diameter and height of the bottles, as well as the type of caps and bottle openings.

- Protective features:

Plastic bottles are also designed to protect the product from external factors such as light, moisture, and oxidation. This feature is particularly important in pharmaceutical packaging, where the product must be protected from factors that could be harmful to human health.

2. Some types of plastics used in pharmaceutical packaging production and their advantages

There are several types of plastics used in pharmaceutical packaging production, depending on the product's requirements and regulatory requirements. Here are some common types of plastics and their advantages:

Polyethylene (PE): PE is a flexible and durable plastic, often used for liquid and powder packaging products. PE is waterproof, resistant to permeation, and UV-resistant.

Polypropylene (PP): PP is a widely used plastic in the packaging industry, known for its waterproof, permeation resistance, and good load-bearing capacity. PP is used for packaging products such as bags, boxes, bottles, and jars.

Polyvinyl chloride (PVC): PVC is a soft and flexible plastic with resistance to high temperatures and waterproofing capabilities. PVC is used for packaging products like bags, bottles, jars, and boxes.

Polycarbonate (PC): PC is a highly durable plastic with good impact resistance and heat resistance, making it suitable for packaging bottles and jars.

Polyethylene terephthalate (PET): PET is a hard and transparent plastic with good heat resistance and impact resistance. PET is used for packaging bottles, jars, and boxes.

Depending on the intended use and product requirements, these plastic types have their own advantages, such as high durability, flexibility, load-bearing capacity, waterproofing, and permeation resistance. Choosing the appropriate plastic type will help protect the product better and ensure the quality of pharmaceutical products.

3. Protective features of plastic packaging for pharmaceuticals

Plastic packaging for pharmaceuticals has protective features to safeguard the pharmaceutical products from external factors such as light, moisture, dust, bacteria, oxidation, and the effects of various environmental factors. The protective features of plastic packaging for pharmaceuticals include:

- Moisture resistance

: Plastic pharmaceutical packaging has moisture-resistant properties to prevent the product from absorbing moisture or becoming wet during storage and transportation.

- Oxidation resistance

: Plastic pharmaceutical packaging has oxidation resistance, protecting pharmaceutical products from the oxidation process and ensuring product quality.

- UV protection

: Plastic pharmaceutical packaging has UV protection capabilities, safeguarding pharmaceutical products from the effects of sunlight and ensuring product stability.

- Sealing properties

: Plastic pharmaceutical packaging has a high degree of sealing, preventing the infiltration of bacteria and external agents into the product.

- Temperature resistance

: Plastic pharmaceutical packaging has temperature resistance, protecting pharmaceutical products from temperature fluctuations during transportation and storage.

In summary, the protective features of plastic packaging for pharmaceuticals are essential to ensure the quality and safety of pharmaceutical products during storage and transportation.

' For more information and consultation, please contact:

Hotline:

Website: pavicovietnam.com

:

' See more plastic products at: https://pavicovietnam.com

Office: No. 4 Lot TT03, Lane 2 Ham Nghi, My Dinh Ward, Nam Tu Liem District, Hanoi

Factory: Lot E1, Trung Ha Industrial Park, Dan Quyen, Tam Nong, Phu Tho

For more information, please visit 50ml Perfume Bottle Wholesale.

Choosing the Right LPG Gas Cylinder: Size, Capacity, and Usage Considerations

Advantages and Applications of Seamless Steel Cylinder

Where Can I Find Custom Jewelry Packaging Suppliers?

Benefits of UV Curable Ink in Screen and Digital Printing

What are the Uses of Sticky Sublimation Paper?

Non-Wet Strength Metallized Paper: Revolutionizing Packaging Solutions

Choosing the Perfect Industrial Barcode Printer for Your Business

159

0

0

All Comments (0)

Previous: Cell Culture Basics: Equipment, Fundamentals and Protocols

Next: White Painted and Distressed Mason Jar, Tip Jar for Money ...

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments