The Process Overview of Acetic Acid Plant

Acetic acid is a vital organic compound with widespread applications in various industries. From food preservation to the manufacturing of chemicals, plastics, and pharmaceuticals, acetic acid plays a significant role. This article will provide a comprehensive guide to understanding the acetic acid plant, the production process, its applications, and future trends in the industry.

What is Acetic Acid?

Acetic acid, also known as ethanoic acid, is a clear, colorless liquid with a pungent odor and a sour taste. It is a weak acid but highly corrosive in concentrated form. The chemical formula for acetic acid is CH3COOH, and it is a crucial component of vinegar, which typically contains around 4-8% acetic acid.

History of Acetic Acid Production

The history of acetic acid production dates back thousands of years when early civilizations discovered the process of fermenting alcoholic liquids to produce vinegar. However, it wasn't until the 19th century that industrial-scale production of acetic acid began with the advent of more efficient processes.

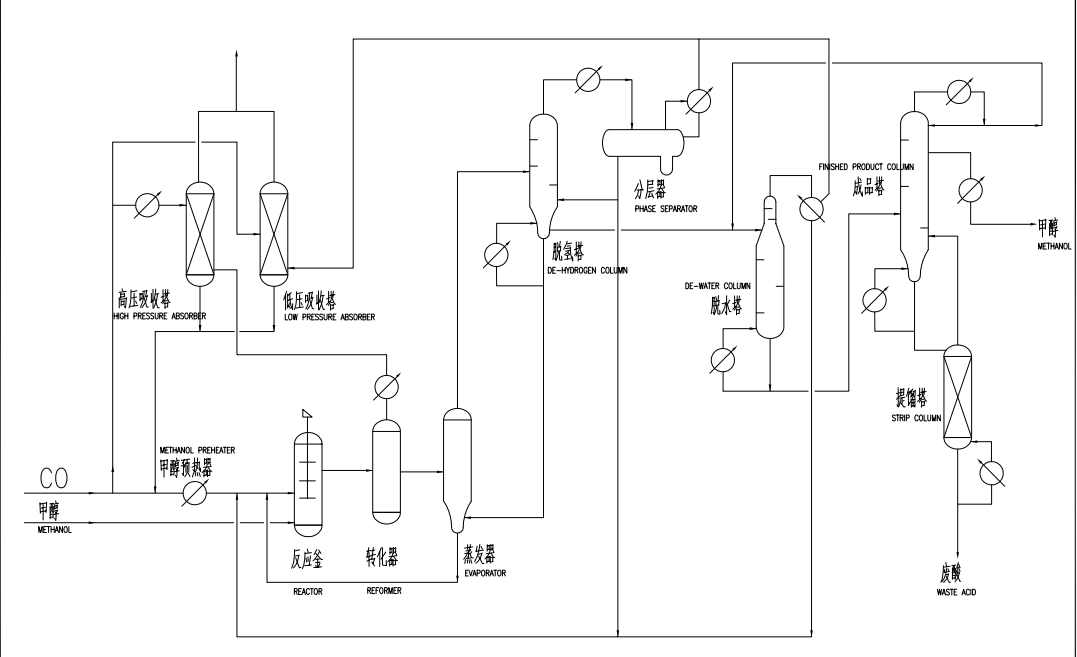

The Acetic Acid Plant: Process Overview

Feedstock Preparation

The first step in the acetic acid production process is the preparation of the feedstock, which is primarily ethanol. Ethanol can be derived from various sources, including corn, sugarcane, and molasses. The feedstock undergoes purification to remove impurities and ensure a high-quality starting material.

Fermentation

During fermentation, the purified ethanol is converted into acetic acid with the help of acetic acid bacteria. This microbial process involves the oxidation of ethanol to acetic acid, with water and carbon dioxide as byproducts.

Distillation

After fermentation, the acetic acid solution is subjected to distillation. Distillation is a crucial step to separate acetic acid from the water and other components present in the solution. This process ensures the production of high-purity acetic acid.

Purification

In the purification stage, any remaining impurities and water are removed from the acetic acid through various techniques, including filtration and chemical treatments. This step is essential to meet the stringent purity standards required for commercial applications.

209

0

0

All Comments (0)

Previous: How to Choose the Right Induction Heater for Forging

Next: How are CNC lathe machines used in modern manufacturing processes?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments