The Benefits of Using flanged uhmwpe pipe

Jun. 24, 2024

What are the Advantages of the UHMWPE Pipe Construction ...

As a UHMWPE Pipe Manufacturers, share with you.

What are the Advantages of the UHMWPE Pipe Construction ...

As a UHMWPE Pipe Manufacturers, share with you.

UHMWPE Pipe technology is now very mature, and many projects have adopted this wear-resistant pipe, which is a moderately priced pipe with excellent performance. The following describes the advantages of UHMWPE wear-resistant pipes in the construction process.

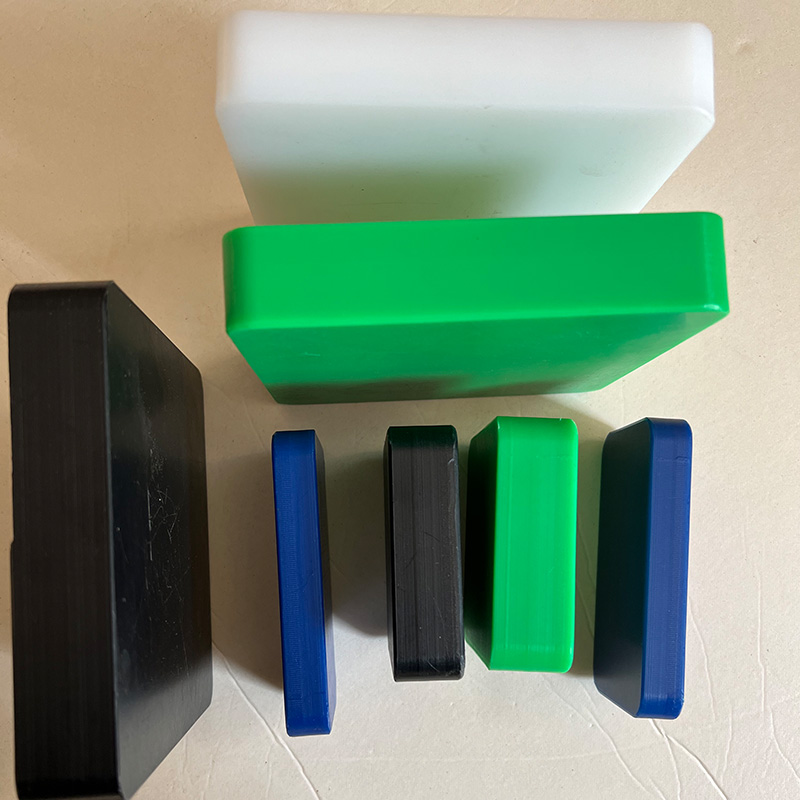

UHMWPE Conveyor Roller Sleeve

High construction efficiency, ultra-high molecular weight polyethylene wear-resistant pipes are light in weight and flexible, easy to load and unload, transport, install and use, which can greatly improve engineering construction efficiency and reduce transportation and installation costs.

Flange connection is fast and convenient. UHMWPE wear-resistant pipes are flanged and fastened with bolts through the pipe's own flange. The connection speed is fast, the disassembly is convenient, the strength is high, and the sealing is good; the joint of the pipe joint does not need anti-corrosion Handling, convenient daily maintenance and repair, reduced installation and maintenance costs, and improved economic efficiency.

The maintenance cost is low, and the UHMWPE wear-resistant pipes have excellent wear resistance. Under the same conditions of use, the service life is longer than that of some traditional wear-resistant pipes of metal type, which can reduce the maintenance work during use and extend the The replacement cycle of pipelines reduces the overall cost of pipeline engineering projects.

UHMWPE pipe is a kind of polyethylene plastic pipe with good abrasion resistance. It has excellent pipe performance and is widely used. The following allows you to understand and choose UHMWPE pipe products suitable for your use.

When the molecular weight of the UHMWPE pipe is 2.5 million, the surface strength is higher after repeated impact, and as the molecular weight increases, the impact resistance is higher. When the impact resistance of the pipe is high, the ultra-high molecular weight polyethylene pipe with a high molecular weight should be selected.

The wear resistance of UHMWPE pipe is very good, and its wear resistance is outstanding. It is widely used in the transportation of slurry materials, ore slurry, mortar, mortar, mud, tailings, seawater and other fields. Ultra-high molecular weight polyethylene pipe is not high enough in hardness and is not suitable for conveying materials containing sharp large particles, which is easily scratched by sharp objects.

Our company also has UHMWPE Conveyor Roller Sleeve on sale, please contact us.

Exploring the Benefits of Using Flanged UHMWPE Pipe

Flanged UHMWPE pipe is a popular choice for various industries due to its many benefits. Let's explore some of the advantages of using this type of pipe and how it can be beneficial for your specific application.

### Step 1: Understand the Benefits of Flanged UHMWPE Pipe.

Flanged UHMWPE pipe is known for its excellent wear resistance, high impact strength, and low coefficient of friction. These properties make it ideal for applications where abrasion and corrosion are common concerns.

### Step 2: Consider Your Application.

Before choosing a flanged UHMWPE pipe, it's important to consider your specific application requirements. Determine the size, pressure rating, and temperature range needed for your project to ensure the pipe will meet your needs.

### Step 3: Evaluate the Cost.

While flanged UHMWPE pipe may have a higher upfront cost compared to other materials, its long lifespan and low maintenance requirements can lead to cost savings in the long run. Consider the total cost of ownership when evaluating different pipe materials.

### Step 4: Choose the Right Flange Type.

Flanged UHMWPE pipe is available with various types of flanges, including slip-on, weld neck, and lap joint. Selecting the right flange type for your application is crucial to ensuring a proper and secure connection.

### Step 5: Installation and Maintenance.

Proper installation and maintenance are key to maximizing the benefits of using flanged UHMWPE pipe. Follow manufacturer guidelines for installation and regularly inspect the pipe for signs of wear or damage to prevent costly repairs.

### Step 6: Monitor Performance.

After installation, monitor the performance of the flanged UHMWPE pipe to ensure it is meeting your expectations. Keep track of any issues or improvements needed to optimize the pipe's performance in your specific application.

### Conclusion.

Overall, the benefits of using flanged UHMWPE pipe are significant and can lead to improved efficiency, reduced downtime, and cost savings for your operation. By following these steps and carefully considering your application requirements, you can harness the advantages of this versatile pipe material.

For more information, please visit flanged uhmwpe pipeflanged uhmwpe pipe, mooring products, hdpe pipe floater.

UHMWPE Pipe technology is now very mature, and many projects have adopted this wear-resistant pipe, which is a moderately priced pipe with excellent performance. The following describes the advantages of UHMWPE wear-resistant pipes in the construction process.

UHMWPE Conveyor Roller Sleeve

High construction efficiency, ultra-high molecular weight polyethylene wear-resistant pipes are light in weight and flexible, easy to load and unload, transport, install and use, which can greatly improve engineering construction efficiency and reduce transportation and installation costs.

Flange connection is fast and convenient. UHMWPE wear-resistant pipes are flanged and fastened with bolts through the pipe's own flange. The connection speed is fast, the disassembly is convenient, the strength is high, and the sealing is good; the joint of the pipe joint does not need anti-corrosion Handling, convenient daily maintenance and repair, reduced installation and maintenance costs, and improved economic efficiency.

The maintenance cost is low, and the UHMWPE wear-resistant pipes have excellent wear resistance. Under the same conditions of use, the service life is longer than that of some traditional wear-resistant pipes of metal type, which can reduce the maintenance work during use and extend the The replacement cycle of pipelines reduces the overall cost of pipeline engineering projects.

UHMWPE pipe is a kind of polyethylene plastic pipe with good abrasion resistance. It has excellent pipe performance and is widely used. The following allows you to understand and choose UHMWPE pipe products suitable for your use.

When the molecular weight of the UHMWPE pipe is 2.5 million, the surface strength is higher after repeated impact, and as the molecular weight increases, the impact resistance is higher. When the impact resistance of the pipe is high, the ultra-high molecular weight polyethylene pipe with a high molecular weight should be selected.

The wear resistance of UHMWPE pipe is very good, and its wear resistance is outstanding. It is widely used in the transportation of slurry materials, ore slurry, mortar, mortar, mud, tailings, seawater and other fields. Ultra-high molecular weight polyethylene pipe is not high enough in hardness and is not suitable for conveying materials containing sharp large particles, which is easily scratched by sharp objects.

Our company also has UHMWPE Conveyor Roller Sleeve on sale, please contact us.

Exploring the Benefits of Using Flanged UHMWPE Pipe

Flanged UHMWPE pipe is a popular choice for various industries due to its many benefits. Let's explore some of the advantages of using this type of pipe and how it can be beneficial for your specific application.

The company is the world’s best light weight hdpe dredging pipe supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Featured content:When to Use nylon monofilament yarn?

How to prevent latex gloves from turning yellow?

Maximize Filtration Efficiency with Belt Press Filter Cloth

Top ODM Abrasion Resistant Hydraulic Hose Exporters

Solving Common Dredge Hose FAQs: Your Ultimate Guide!

How to Choose ODM Abrasion Resistant Hydraulic Hose

4 Advice to Choose the Right Polyurethane Hydrocyclone

### Step 1: Understand the Benefits of Flanged UHMWPE Pipe.

Flanged UHMWPE pipe is known for its excellent wear resistance, high impact strength, and low coefficient of friction. These properties make it ideal for applications where abrasion and corrosion are common concerns.

### Step 2: Consider Your Application.

Before choosing a flanged UHMWPE pipe, it's important to consider your specific application requirements. Determine the size, pressure rating, and temperature range needed for your project to ensure the pipe will meet your needs.

### Step 3: Evaluate the Cost.

While flanged UHMWPE pipe may have a higher upfront cost compared to other materials, its long lifespan and low maintenance requirements can lead to cost savings in the long run. Consider the total cost of ownership when evaluating different pipe materials.

### Step 4: Choose the Right Flange Type.

Flanged UHMWPE pipe is available with various types of flanges, including slip-on, weld neck, and lap joint. Selecting the right flange type for your application is crucial to ensuring a proper and secure connection.

### Step 5: Installation and Maintenance.

Proper installation and maintenance are key to maximizing the benefits of using flanged UHMWPE pipe. Follow manufacturer guidelines for installation and regularly inspect the pipe for signs of wear or damage to prevent costly repairs.

### Step 6: Monitor Performance.

After installation, monitor the performance of the flanged UHMWPE pipe to ensure it is meeting your expectations. Keep track of any issues or improvements needed to optimize the pipe's performance in your specific application.

### Conclusion.

Overall, the benefits of using flanged UHMWPE pipe are significant and can lead to improved efficiency, reduced downtime, and cost savings for your operation. By following these steps and carefully considering your application requirements, you can harness the advantages of this versatile pipe material.

For more information, please visit flanged uhmwpe pipe, mooring products, hdpe pipe floater.

What are the Advantages of the UHMWPE Pipe Construction ...

As a UHMWPE Pipe Manufacturers, share with you.

UHMWPE Pipe technology is now very mature, and many projects have adopted this wear-resistant pipe, which is a moderately priced pipe with excellent performance. The following describes the advantages of UHMWPE wear-resistant pipes in the construction process.

UHMWPE Conveyor Roller Sleeve

High construction efficiency, ultra-high molecular weight polyethylene wear-resistant pipes are light in weight and flexible, easy to load and unload, transport, install and use, which can greatly improve engineering construction efficiency and reduce transportation and installation costs.

Flange connection is fast and convenient. UHMWPE wear-resistant pipes are flanged and fastened with bolts through the pipe's own flange. The connection speed is fast, the disassembly is convenient, the strength is high, and the sealing is good; the joint of the pipe joint does not need anti-corrosion Handling, convenient daily maintenance and repair, reduced installation and maintenance costs, and improved economic efficiency.

The maintenance cost is low, and the UHMWPE wear-resistant pipes have excellent wear resistance. Under the same conditions of use, the service life is longer than that of some traditional wear-resistant pipes of metal type, which can reduce the maintenance work during use and extend the The replacement cycle of pipelines reduces the overall cost of pipeline engineering projects.

UHMWPE pipe is a kind of polyethylene plastic pipe with good abrasion resistance. It has excellent pipe performance and is widely used. The following allows you to understand and choose UHMWPE pipe products suitable for your use.

When the molecular weight of the UHMWPE pipe is 2.5 million, the surface strength is higher after repeated impact, and as the molecular weight increases, the impact resistance is higher. When the impact resistance of the pipe is high, the ultra-high molecular weight polyethylene pipe with a high molecular weight should be selected.

The wear resistance of UHMWPE pipe is very good, and its wear resistance is outstanding. It is widely used in the transportation of slurry materials, ore slurry, mortar, mortar, mud, tailings, seawater and other fields. Ultra-high molecular weight polyethylene pipe is not high enough in hardness and is not suitable for conveying materials containing sharp large particles, which is easily scratched by sharp objects.

Our company also has UHMWPE Conveyor Roller Sleeve on sale, please contact us.

Exploring the Benefits of Using Flanged UHMWPE Pipe

Flanged UHMWPE pipe is a popular choice for various industries due to its many benefits. Let's explore some of the advantages of using this type of pipe and how it can be beneficial for your specific application.

### Step 1: Understand the Benefits of Flanged UHMWPE Pipe.

Flanged UHMWPE pipe is known for its excellent wear resistance, high impact strength, and low coefficient of friction. These properties make it ideal for applications where abrasion and corrosion are common concerns.

### Step 2: Consider Your Application.

Before choosing a flanged UHMWPE pipe, it's important to consider your specific application requirements. Determine the size, pressure rating, and temperature range needed for your project to ensure the pipe will meet your needs.

### Step 3: Evaluate the Cost.

While flanged UHMWPE pipe may have a higher upfront cost compared to other materials, its long lifespan and low maintenance requirements can lead to cost savings in the long run. Consider the total cost of ownership when evaluating different pipe materials.

### Step 4: Choose the Right Flange Type.

Flanged UHMWPE pipe is available with various types of flanges, including slip-on, weld neck, and lap joint. Selecting the right flange type for your application is crucial to ensuring a proper and secure connection.

### Step 5: Installation and Maintenance.

Proper installation and maintenance are key to maximizing the benefits of using flanged UHMWPE pipe. Follow manufacturer guidelines for installation and regularly inspect the pipe for signs of wear or damage to prevent costly repairs.

### Step 6: Monitor Performance.

After installation, monitor the performance of the flanged UHMWPE pipe to ensure it is meeting your expectations. Keep track of any issues or improvements needed to optimize the pipe's performance in your specific application.

### Conclusion.

Overall, the benefits of using flanged UHMWPE pipe are significant and can lead to improved efficiency, reduced downtime, and cost savings for your operation. By following these steps and carefully considering your application requirements, you can harness the advantages of this versatile pipe material.

For more information, please visit flanged uhmwpe pipe, mooring products, hdpe pipe floaterhdpe pipe floater.

Ultimate Guide to Steel Wire Braided Hoses

How to properly size a dredge discharge hose?

How Does Metal Roofing Work?

What makes ODM polyurethane hose so durable?

Exploring the Benefits of Using ODM Chemical Corrosion Resistant PTFE Hose

4 Tips for Selecting a Metal Corrugated Compensator for Your Heating System

Essential Guide to Rubber Bellow Hose Assemblies

114

0

0

All Comments (0)

Previous: When to Use HDPE Pipe?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments