Mud Mat for Construction Site Mud Control - 4' x 8' - Tan

Jun. 10, 2024

Mud Mat for Construction Site Mud Control - 4' x 8' - Tan

Determine The Ground Conditions Before Starting A Project

You can find more information on our web, so please take a look.

Before starting a project, you have to determine the condition of the soil such as rocky, grassy, or sandy. Does the ground slope, is it muddy, or extremely dry? Determine the soil condition, then decide what matting you want to use for the project. Ground protection mats will conform to just about all ground conditions. You can overlap flanges and use locking pins to reduce gaps and breaks that can cause excessive wear and possibly damage to equipment as well as placing your workers in harm's way.

You should ask as many questions as possible regarding the soil condition of the site, the bearing capacity of the sub-grade, the load and traffic requirements, and the time frame of the project. This information can have an impact on the number of mats and the configuration of your road or work site. These issues are best addressed by a GeoEngineer or the project manager before installation begins.

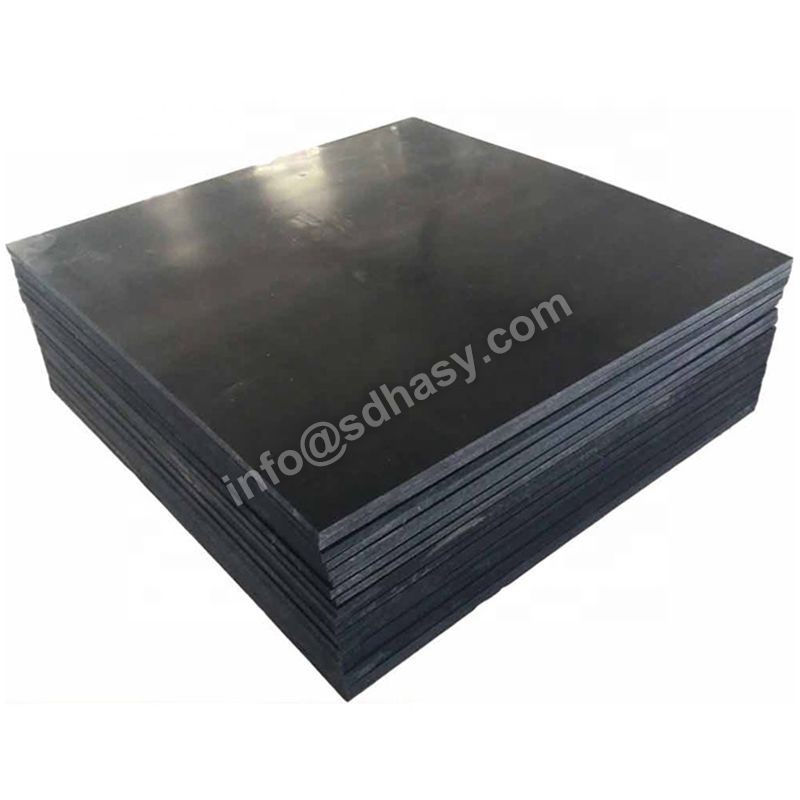

Ground protection mats are designed to withstand over time and not deteriorate from wear and tear which can not be said about plywood boards. Ground protection mats will continue to be a valuable application for protecting the ground and not breaking under pressure. These mats will not warp which otherwise would prevent them from lying flat on the surface.

Ground protection mats are designed to withstand over time and not deteriorate from wear and tear which can not be said about plywood boards. Ground protection mats will continue to be a valuable application for protecting the ground and not breaking under pressure. These mats will not warp which otherwise would prevent them from lying flat on the surface.

Temporary road dry hire, the pros and cons

Temporary road dry hire, the pros and cons

Here at Davis Trackhire, we are a hire-only business and predominantly offer a full-service setup, however if specifically requested, we can accommodate for temporary road dry hire.

Dry hire is a simpler agreement that covers the hire of our trackway products only, (plus a dry hire method statement if hiring heavy-duty panels). It does not include our usual comprehensive agreement, which is complete with a site survey, RAMS risk assessment, delivery, installation, removal, and collection.

With competitive price and timely delivery, XINXINGHUAGONG sincerely hope to be your supplier and partner.

Featured content:How to Choose Ssaw Pipes for Your Next Construction Project?

How easy is it to make your own die?

WHY CUSTOM-MADE TABLE AND HOW TO PICK ONE

The Ultimate Guide to Choosing Bespoke Pipe Clamps

Why is Pipe Fittings Supplier Better?

How Does Flange Supplier Work?

Applications and Uses of Geocell in Civil Engineering

Most construction projects require temporary roads in one shape or form. Companies have different options when it comes to laying a temporary road. Depending on the size of the company, experience, skill set, storage space, budget and crew size contribute to which option they might choose.

Very large, established, construction companies often have their own temporary road panels, machinery to complete the job, a storage facility to hold them, and trained professionals to install them. At the opposite end of the spectrum are companies that hire the complete package from us, our temporary road panels plus our full service. Then finally, there are those in between who will dry hire. They only require our trackway, as their staff is trained in the installation, they have the machinery to install, and the insurance to cover themselves too.

But, which is the better option? Which works out the safest, most cost-effective, and most efficient?

Here are the pros of temporary road dry hire

Cost savings

Of course, this is top of the list. The main advantage of dry hiring temporary road panels is cost efficiency. By removing handling, surveys, installation and removal costs it reduce the overall cost of the hire rental price. You don't have to pay for our time, staff and expertise.

Utilizing in-house staff

You may have hired staff with a trackway installation checkbox on their CV for this intention. Alternatively, you may have invested in training to upskill them. Either way, this means you keep all work internal and spend your budget on paying your own staff more.

Communication & flexibility

Some companies find it easier not to have to relay information to a third party. They like the option of being able to lay out the temporary road with more design freedom. It also gives them the option to move it around the site where required at no additional cost.

Here are the cons of temporary road dry-hire

Skill maintenance

Although having an in-house trackway team may seem like an ideal scenario, in reality, it could be tricky. If the team are laying temporary roads infrequently (not on a day-to-day basis) then their skills may become impaired. Training updates, upkeep of skills, and constant practice can be difficult to maintain. This is particularly so if it is not the worker's main skill or job role. Alternatively, if you have dedicated staff is there enough work to fill their time?

Temporary road equipment cost

Specialised equipment can be costly. Companies may only purchase the basic installation and removal equipment. However, they may require unexpected components to suit specific jobs further down the line.

The insurance

If something goes wrong, your company will be liable. If the temporary road was not laid where it was required, installed incorrectly, or the incorrect quantity laid then this can cause dangerous on-site accidents. This can include overturning vehicles, worker injury, or at the very least costly equipment damage. Local councils can often issue fines and punishments for any damage to public grounds too which you may find yourself liable for.

Costs & time

Not only is there the cost of additional insurance, equipment, trackway, storage facility, and staff training but there is also the cost of your time. Not only can the installation and removal process be time-consuming without state-of-the-art trucks and equipment like ours, but afterward all the mats need to be cleaned and quality checked. All these factors can cause project delays and delays on you starting your next project.

All in all, the decision you make should align with your project's specific needs and your business and staff capabilities. However, we of course will always promote our own full-service hire and professional installation services as we are confident that this is the safest, most affordable, and logistically freeing choice for most businesses.

You can view our hire process, here. Feel free to contact us if you have any questions.

For more plastic road matsinformation, please contact us. We will provide professional answers.

Non Woven Geotextile vs. Woven Geotextile: A Comparison

LVL Scaffolding Plank: The Ultimate Solution for Sturdy and Efficient Construction Work

Features and Advantages of Welded Gabion Wire Mesh

Advantages and Disadvantages of PVC Water Supply Pipes

Enhancing Tile Adhesive Performance with HPMC: Key Considerations and Applications

What is the difference between rubber and foam rubber?

Laminated Bridge Bearings: Enhancing Safety and Structural Performance

92

0

0

All Comments (0)

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments