Maximize Production Efficiency with 10L Bottle Blow Molding Machine

Mar. 26, 2024

Are you looking to maximize your production efficiency with a 10L bottle blow molding machine? Look no further! In this article, we will discuss how this machine can help you streamline your production process and increase output.

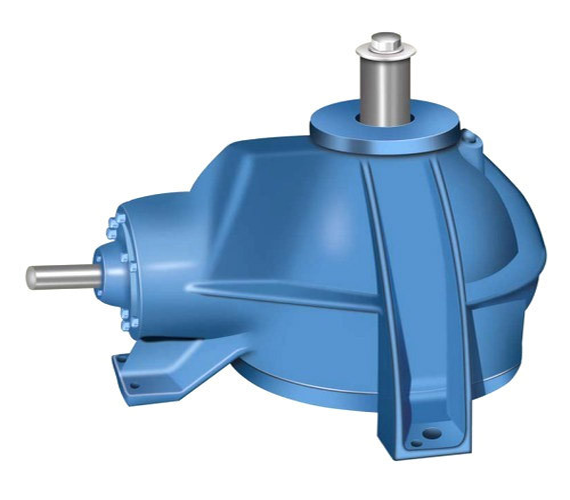

What is a 10L Bottle Blow Molding Machine?

A 10L bottle blow molding machine is a piece of equipment used in the manufacturing industry to produce large plastic bottles. These machines use a process called blow molding to create hollow plastic containers. The machine heats up plastic resin to a molten state and then uses air pressure to blow the plastic into a mold, creating a bottle shape.

Benefits of Using a 10L Bottle Blow Molding Machine.

1. Faster Production Speed: With a 10L bottle blow molding machine, you can produce bottles at a much faster rate compared to traditional methods. This can help you meet tight production deadlines and increase your overall output.

2. Cost-Effective: Investing in a 10L bottle blow molding machine can help you save on production costs in the long run. These machines are energy-efficient and require minimal maintenance, making them a cost-effective solution for your manufacturing needs.

3. Versatile: 10L bottle blow molding machines are versatile and can be used to produce a wide range of bottle sizes and shapes. This flexibility allows you to cater to different market demands and expand your product offerings.

4. High-Quality Output: The bottles produced by a 10L bottle blow molding machine are of high quality, with consistent thickness and clarity. This can help enhance your brand image and attract more customers to your products.

Featured content:10 Questions You Should Know About High Speed Blowing Machine Special for PP Infusion Bottle

Pet Bottle Blowing Machine Costs: Used vs. New

The Benefits of Using Turnover Box Injection Mould Zone

How Does 3D printing technology Work?

How to Start a Disposable Blood Lancet and Insulin Pen ...

Unique Features Of Mini Concrete Batching Plants

What are the uses of mobile tower crane?

How to Maximize Production Efficiency with a 10L Bottle Blow Molding Machine.

So, how can you make the most out of your 10L bottle blow molding machine? Here are some tips:

1. Optimize Machine Settings: Adjust the machine settings to ensure optimal production efficiency. This includes setting the right temperature, pressure, and cycle time for the type of plastic resin you are using.

2. Train Operators: Proper operator training is crucial for maximizing production efficiency. Make sure your staff is well-trained in operating the machine to minimize downtime and prevent errors.

3. Regular Maintenance: Keep your 10L bottle blow molding machine in top condition by performing regular maintenance checks. This will help prevent breakdowns and ensure smooth operation.

4. Quality Control: Implement a strict quality control process to ensure that all bottles produced meet the required standards. This will help reduce waste and improve overall production efficiency.

In conclusion, a 10L bottle blow molding machine is a valuable tool for manufacturers looking to increase production efficiency. By following the tips mentioned above, you can make the most out of your machine and achieve higher output levels. If you are interested in investing in a 10L bottle blow molding machine, contact us to learn more about our products and services. Our experienced team of suppliers can help you find the right solution for your manufacturing needs.

Want more information on EPE foam bonding machine for sale, EPE foam sheet co-extrusion machine, 1L jerry can blow molding machine? Feel free to contact us.

Featured content:Chiller Problems and Solutions: Keeping Your Cooling System in Top Shape

How to Increase Welding Productivity with a Positioner

How Does The Rising Film Evaporator Work?

Top 10 conveyor roller Manufacturers

Advancing Surface Finishing: The Skiving Roller Burnishing Machine

The 10 Best Welding Machines in 2023

A Comprehensive Guide to Plasma Cutters

116

0

0

All Comments (0)

Previous: 10 Questions You Should Know About High Speed Blowing Machine Special for PP Infusion Bottle

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments