Mastering the Fixed Bed Process: A Guide

May. 10, 2024

The fixed bed processfixed bed process is a widely used technique in chemical engineering for various applications such as catalysis, adsorption, and gas-solid reactions. Mastering this process is crucial for achieving optimal performance and efficiency in industrial processes.

In this guide, we will delve into the key aspects of the fixed bed process and provide insights on how to master it effectively. Whether you are a seasoned professional looking to enhance your skills or a newcomer to the field seeking to gain a solid understanding, this guide is tailored to meet your needs.

Key Components of the Fixed Bed Process.

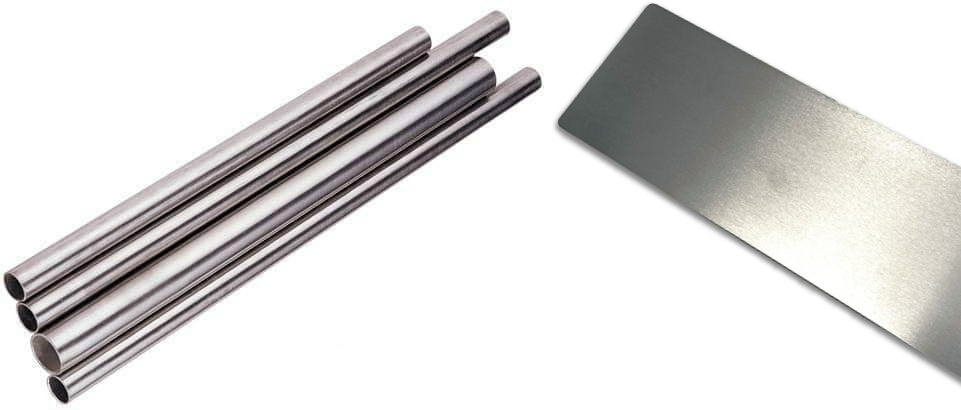

The fixed bed process involves passing a fluid through a bed of solid particles, where the fluid may undergo various physical and chemical transformations. The key components of the fixed bed process include the reactor vessel, the solid bed, and the fluid flow system.

The reactor vessel is designed to house the solid bed and control the flow of the fluid through it. It is essential to ensure good mixing and uniform distribution of the fluid within the bed to promote efficient mass transfer and reaction kinetics.

The solid bed consists of packed particles that serve as the active sites for the desired reactions or adsorption processes. The size, shape, and composition of the particles play a crucial role in determining the overall performance of the fixed bed system.

The fluid flow system is responsible for delivering the fluid to the reactor vessel at the desired flow rate and pressure. Proper design and optimization of the flow system are essential to ensure smooth operation and avoid any potential issues such as channeling or bed collapse.

Mastering the Fixed Bed Process: Tips and Techniques.

To master the fixed bed process effectively, it is important to consider the following tips and techniques:

1. Understanding the Kinetics: A thorough understanding of the reaction kinetics and mass transfer mechanisms occurring within the fixed bed is essential for optimizing the process parameters. This includes studying the rate-determining steps, diffusion limitations, and heat/mass transfer effects that influence the overall performance of the system.

Featured content:Chemicals

Key Questions to Ask When Ordering Magnesium Oxide Chemical

10 Questions You Should Know about What is the chemical name for CAS 36265-41-5

11 Types of Magnesium and Their Benefits

Theophylline: Uses, Interactions, Mechanism of Action

Unlocking the Benefits of CAS 4579-64-0: Everything You Need to Know

Where to buy 2 bromo 4 methylpropiophenone?

2. Proper Bed Design: The design of the solid bed plays a critical role in determining the efficiency and effectiveness of the fixed bed process. Factors such as particle size distribution, bed porosity, and bed height must be carefully considered to maximize the surface area and promote uniform fluid distribution.

3. Flow Optimization: The flow rate, pressure, and composition of the fluid passing through the fixed bed must be optimized to ensure effective interaction with the solid particles. Computational fluid dynamics (CFD) simulations and experimental testing can help identify potential flow issues and improve mixing within the bed.

4. Catalyst Selection: Choosing the right catalyst for the desired reaction is crucial for achieving high selectivity and conversion rates. Factors such as catalytic activity, stability, and regeneration potential should be considered when selecting the catalyst for the fixed bed process.

5. Monitoring and Control: Continuous monitoring of key process parameters such as temperature, pressure, and flow rate is essential for maintaining stable operation and detecting any deviations or anomalies. Automated control systems can help adjust the process conditions in real-time to optimize performance.

6. Scale-Up Considerations: When scaling up the fixed bed process from the lab to industrial production, factors such as reactor size, process safety, and capital costs should be carefully evaluated. Pilot testing and feasibility studies can help assess the scalability of the process and identify potential challenges.

Conclusion.

Mastering the fixed bed process requires a combination of theoretical knowledge, practical experience, and attention to detail. By understanding the key components of the process, optimizing the design and operation parameters, and continuously monitoring the performance, one can achieve superior results and enhance the overall efficiency of industrial processes.

Whether you are a novice exploring the world of chemical engineering or a seasoned professional seeking to refine your skills, mastering the fixed bed process is a valuable asset that can open up new opportunities and drive innovation in the field. With the right tools, techniques, and mindset, mastering the fixed bed process is within reach for anyone willing to take on the challenge.

Are you interested in learning more about trioxane synthesis, acetates production technology? Contact us today to secure an expert consultation!

Featured content:Unveiling the Power of Alpha Bromovalerophenone

How to Choose 100% Safe Shipping CAS 5337-93-9

Key Questions to Ask When Ordering at Home Cryotherapy Chamber

Electric Cryotherapy Guide - Sun Spa ...

How to use a home cryotherapy chamber?

Redispersible Polymer Powder Market Size & Share ...

Hyperbaric Chambers: Are They the Ultimate Cure?

127

0

0

All Comments (0)

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments