Induction heating equipment for sale 2023

An induction heater is a device that uses electromagnetic induction to heat a material or object by generating eddy currents within it. This technology is widely used in various industrial and commercial applications for heating, brazing, soldering, annealing, hardening, and other thermal processes. Induction heating offers several advantages, including precise and controllable heating, rapid heating rates, and minimal heat loss to the surroundings.

1 2.5KW~20KW 220V-1P Wall-mounted Induction Heating Water Boiler

Model No.: ZG-EH2.5HB-H, ZG-EH3.5HB-H, ZG-EH05HB-H, ZG-EH06HB-H, ZG-EH08HB-H, ZG-EH10HB-H, ZG-EH12HB-H

Rated Power: 2.5kw~12kw

Container Materials; aluminum alloy shell with tempered glass panel, which is very beautiful in appearance.

Dimension: 420*190*650mm, small in size

Advantages and characteristics of induction heating water boiler

1. High efficiency and energy saving: The thermal efficiency is over 90%. Under the same conditions, it can save more than 30% of electricity than the resistance heating method, and some even save 80% of electricity. The preheating time can be shortened.

2. Reliable operation: Multiple closed-loop intelligent control systems and perfect protection systems ensure long-term safe and reliable operation of the equipment.

3. Reduce production costs: The heating part adopts a cable structure. The heating cable itself does not generate heat and has a long service life. It avoids the need for frequent maintenance and periodic replacement of the heating coil for resistance heating, and there is basically no maintenance cost in the later period.

4. Improve working environment: The heating part has less heat dissipation, and the surface can be touched by hand, which improves the environmental conditions at the production site.

5. Intelligent multi-temperature zone control: The electromagnetic heating economizer uses a LCD screen to display the real-time temperature and set temperature range. The built-in chip can intelligently control the heating speed and output power, and can be flexibly adjusted according to the actual situation. Ultra-high temperature heating electromagnetic heating coils have been applied to manufacturers of plastic products, plastic films, pipes, profiles and similar industries, and have achieved good results. They have the characteristics of convenient installation and strong interchangeability. Better economic benefits than ever.

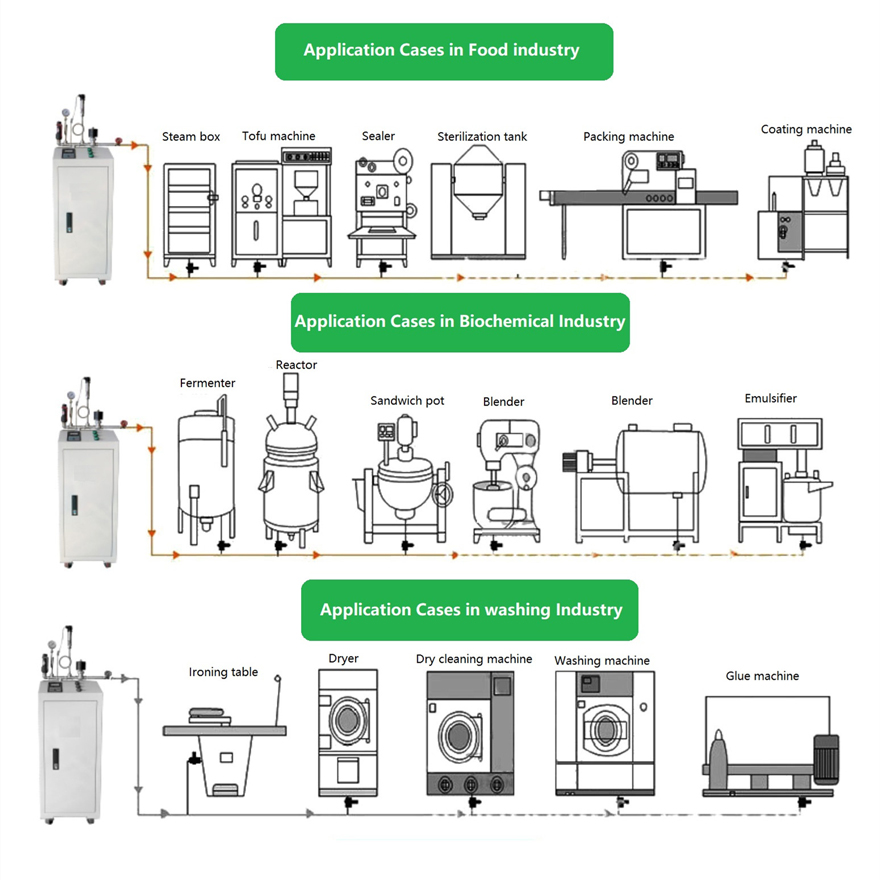

2 ZG-EH-SG Series Electromagnetic Induction Heating Steam Generator

Model No.: ZG-EH3.5-SG, ZG-EH05-SG, ZG-EH06-SG, ZG-EH08-SG, ZG-EH12-SG, ZG-EH16-SG, ZG-EH30-SG, ZG-EH60-SG.

Rated Power: 3.5kw, 5kw, 6kw, 8kw, 12kw, 16kw, 30kw, 60kw

Main Function: heating water to high temperature over 120C degrees and quickly generating steam out.

Main Advantage: Electromagnetic Induction heating steam generator can save at least 30%~50% electricity than resistance wire heating, generating steam very fast within 60S.

MAIN FEATURES

Electromagnetic Induction Heating Steam Generator is using energy saving High-frequency induction heating converting heat energy in a very efficient way and the thermal efficiency can save up to 30%~70% than the traditionaresistance wire heating;

The heating element of Electromagnetic Induction Heating Steam Generator does not need maintenance charges because the heating element will not get high temperature and no cause of burning, which is unlike the traditional heaters that have resistance wire heating and the wires inside easily get burned.

The used steam would become waste water, which can be circling used and the temperature of the waste water is high and easily recycled and heated into steam again, so the energy saving will be saved in this way too;

No requirements of water quality: we can use normal tap water for heating

Rapid heating speed: steam will come out in 60s.

No pollution at all. Production.

No electricity in water and totally safe for human: the Electromagnetic Induction Heating Steam Generator has a built-in steam-water isolation system.

3 15KW 30-100KHz High Frequency Induction Heating Brazing Machine (Water-cooled Type)

Model No.:ZG-HF15 (2 Types for Choice: Unit or Split Type)

Input Power: 220V-1P

Output Working Power: 5-15kw adjustable

Main Function:heat treatment of small metal parts, brazing and welding of tools and blades and pipes etc

Main Advantage: heating speed very quick, temperature can reach to 2500C degrees.

Main Components: Induction Heating Controller (+ Transformer ) + Induction Coil

MAIN FEATURES

(1) Output working frequency can reach to 100Khz according to the loading.

(2) 100% loading duty, which can be working 24 hours per day.

(3) Heating Power can be adjusted from 3kw to 15kw.

(4) Heating time and retaining time can be set up from 1 seconds to 999 seconds.

(5) Water cooling type via chiller or small pump and tank.

(6) Net weight only around 18kgs, easy to transportation.

(7) Auto-protection functions be equipped like over current, over power, water failed, etc.

(8) High frequency induction heater can be worked in 2 modes: manually or automatically by setting.

4 ZG-SF Series 16KW to 320KW /6-50KHZ Super-Audio High Frequency Solid State Induction Heating Quenching Machine (Water Cooling)

Model No.: ZG-SF16, ZG-SF30, ZG-SF40, ZG-SF50, ZG-SF60, ZG-SF80, ZG-SF120, ZG-SF160, ZG-SF250, ZG-SF320

Rated Power: 16kw, 30kw, 40kw, 50kw, 60kw, 80kw, 120kw, 160kw, 250kw, 320kw

Main Function: Diathermy forging heating, hot upsetting and hot rolling heating for various metal parts less than diameter 800mm.

Main Advantage: Oscillation Frequency low to 6-50Khz, with transformer no output high voltage, can heat bigger diameter metal parts than high frequency induction heating machine.

Main Components: Solid State Induction Heating Controller + Transformer + coil

MAIN FEATURES

1. Adopt Siemens IGBT module as power driving part and unique inverter technology from Germany.

2. 100% load rate, can be working 24-hour per day even in maximum power working mode.

3. Automatic control type: heating time, heating power, holding time, holding power and cooling time can be adjusted.

4. Simple operation steps for any new worker can be learned in several minutes.

5. Simple installation, just connecting the 380V three-phase power supply, water inlet and outlet, and it can be completed in a few minutes.

6. It occupies a very small area, the operation is simple, and it can be learned in a few minutes.

7. Especially safe, the output voltage is lower than 36V, avoiding the danger of high voltage electric shock.

8. Heating efficiency is as high as 90% or more, saving energy.

9. Complete automatic protection functions such as over-current, over-voltage, over-temperature, water shortage, and lack of water, and is equipped with a fault self-diagnosis alarm system.

5 ZG-HFW Series Portable/hand-holding/moveable type induction heating brazing machine

See also:Machinery

Single Facer Corrugation Machine: Revolutionizing the Packaging Industry

Exploring the Efficiency and Advantages of Permanent Magnet Synchronous Motors

The Ultimate Guide to DC Small Portable Chillers: Compact Cooling Solutions

How are CNC lathe machines used in modern manufacturing processes?

The Process Overview of Acetic Acid Plant

How to Choose the Right Induction Heater for Forging

Descriptions

Model No.: ZG-HFW10, ZG-HFW20, ZG-HFW30, ZG-HFW40, ZG-HFW60, ZG-HFW80, ZG-HFW100

Rated Power: 10kw, 20kw, 30kw, 40kw, 60kw, 80kw, 100kw

Main Function: Portable induction brazing machine can be used for transformer joint welding, copper tube online welding, surface heating coating, field heating etc.

Main Advantage: with 3-8 meters long moveable brazing head, which move freely and easily for hand-holding.

MAIN FEATURES

Induction brazing is typically faster and more energy-efficient than traditional brazing methods, which can translate into significant cost savings over the long term. Additionally, copper tube induction brazing equipment offers greater precision, as the heat can be precisely controlled and applied only to the necessary areas, reducing the risk of damage to surrounding components.

ZG-HFW series hand-held/portable high frequency induction heating welding machine with 3-8 meters long moveable brazing head, which move freely and easily for hand-holding. The power can be choose from 10-100KW, and the frequency range is from 30KHz to 150KHZ. Portable induction brazing equipment can be used for transformer joint welding, copper tube online welding, surface heating coating, etc. Field heating applications;

However, due to the large difference in the magnetic induction performance of the heating materials, the different heating requirements, and the different shapes and sizes of the induction coils, the equipment needs to be adjusted accordingly to achieve a good heating effect. At present, most of our ZG-HFW Handheld Induction Heating Welding Machine series are all developed for welding copper pipes, and these equipments are not necessarily suitable for other purposes. Therefore, when ordering equipment, you need to provide us with the corresponding information:

(1) The material and size of the heated workpiece;

(2) Information on the purpose of heating, heating temperature, and heating time requirements.

6 ZG-MFF Series 15-300kw Medium Frequency Induction Heating Forging Furnace (Water Cooling)

Model No. | Max. Input Power | Input Voltage | Heating ability of normal material | |

Steel or S.S to 1100 | Copper or brass to 700 | |||

ZG-MFF35 | 35KW | 380V/3P, 50/60HZ | 1.25 KG/min | 1.75 KG/min |

ZG-MFF45 | 45KW | 380V/3P, 50/60HZ | 1.67 KG/min | 2.33 KG/min |

ZG-MFF70 | 70KW | 380V/3P, 50/60HZ | 2.5 KG/min | 3.5 KG/min |

ZG-MFF90 | 90KW | 380V/3P, 50/60HZ | 3.33 KG/min | 4.67 KG/min |

ZG-MFF110 | 110KW | 380V/3P, 50/60HZ | 4.17 KG/min | 5.83 KG/min |

ZG-MFF160 | 160KW | 380V/3P, 50/60HZ | 5.83 KG/min | 8.5KG/min |

ZG-MFF240 | 240KW | 380V/3P, 50/60HZ | 9.2 KG/min | 12 KG/min |

ZG-MFF300 | 300KW | 380V/3P, 50/60HZ | 11.25 KG/min | 15 KG/min |

When selecting the best induction heater for your needs, consider factors such as the type of work you'll be performing, the size and shape of your workpieces, the required temperature and heating time, and your budget. Additionally, look for warranties, customer support, and user reviews to help make an informed decision. Since technology and product availability can change over time, it's a good idea to research the latest models and reviews to find the most suitable induction heater for your specific requirements.

Understanding the PDC Bit: A Key Component of Drilling Operations

How do you manufacture nitrile gloves?

Vertical Shaft Impact Crusher: A Comprehensive Guide to Revolutionize Your Crushing Process

How Does the Puff Snacks Extruding Machine Work?

Benefits and Applications of Automatic Leather Cutting Machines

Types of Scrap Used in Steel Production

What is the difference between telescopic and articulating boom lifts?

194

0

0

All Comments (0)

Previous: A Comprehensive Guide to Plasma Cutters

Next: Everything You Want To Know about Wheat Flour Milling Plant

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments