CN105987171A - Oil seal manufacturing process

Jun. 17, 2024

CNA - Oil seal manufacturing process

Technical field

For more rubber oil seal from china manufacturerinformation, please contact us. We will provide professional answers.

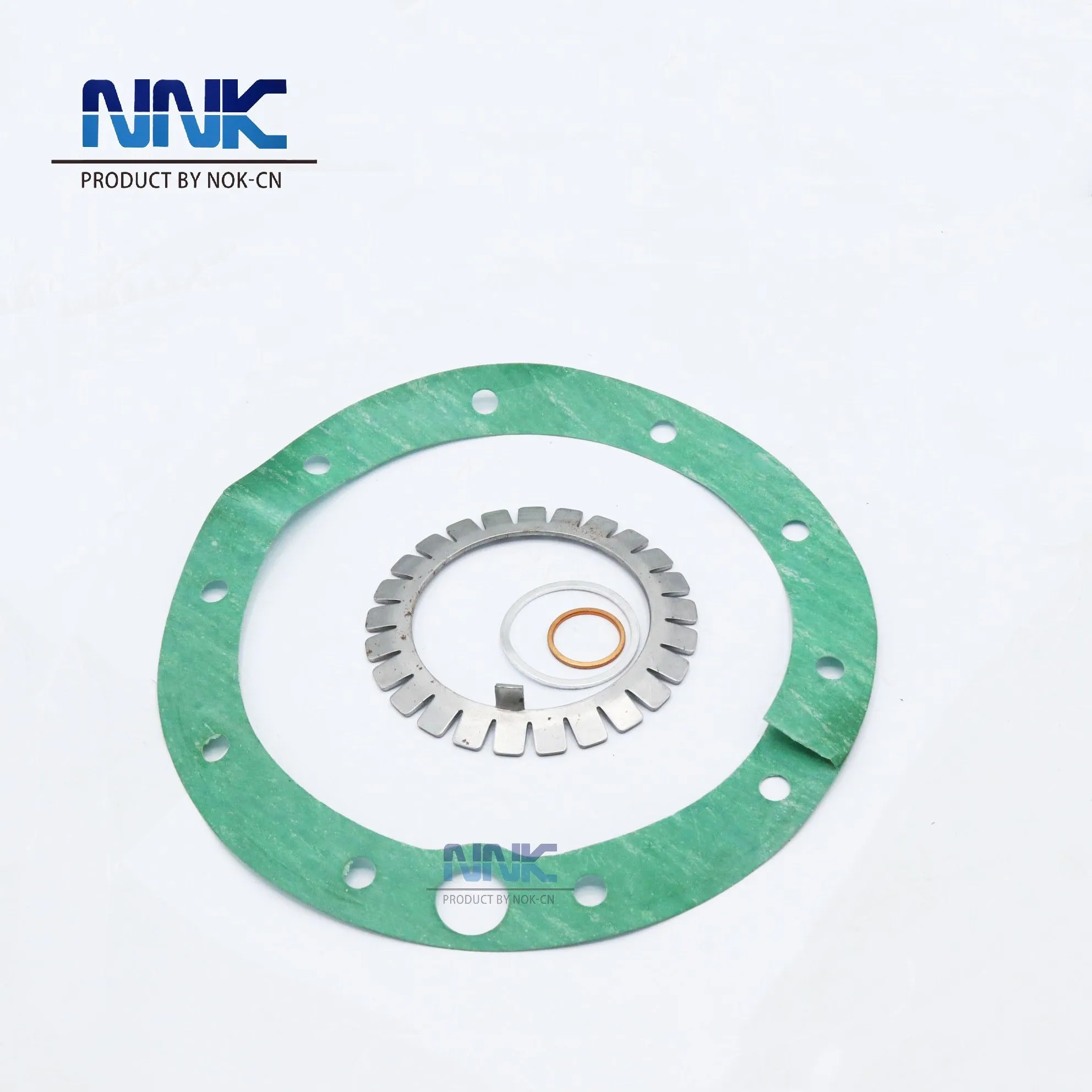

The present invention relates to a kind of oil sealing processing technology.

Background technology

Oil sealing is used to the mechanical organ of oil sealing (oil is modal liquid substance in drive system, also refers to the meaning of general liquid substance), and it will need the parts of lubrication and parts isolation of exerting oneself in drive disk assembly, is unlikely to allow oil seepage.Static seal and movable sealing (typically moving back and forth) with sealing member sealing member.

The technics comparing of oil sealing is complicated at present, the most unified specification, not unified standard, the steel part quality causing production is uneven, a lot of operations that repeat also make under production efficiency, increase the work burden of workman, make the competitiveness of product in market the highest simultaneously.For the operator that some have just been entered a profession, the method technique that neither one is clear and definite, often there are mistakes and omissions when of causing operation, in some instances it may even be possible to cause serious consequence.

Summary of the invention

Because the drawbacks described above of prior art, the technical problem to be solved is to provide a kind of oil sealing processing technology, and this oil sealing processing technology is simple, eliminates a lot of repeatability operation, improves work efficiency.

For achieving the above object, the invention provides a kind of oil sealing processing technology, it is characterised in that comprise the steps, 1) iron-clad returns factory's inspection&#;

2) epithelium: add degreaser and go fat &#; add Phosphating Solution to be processed on iron-clad surface, antirust &#; to add sulfuration liquid to increase iron-clad adhesive force&#;

3) then: soak in the iron-clad solid to be placed on of epithelium, as solid stock solution that acrylic, fourth are fine is the mixed solution of TD870 and ethanol, allocate in the ratio of 1:3.5, typically to soak at twice, iron-clad is put in people's stock solution, will stir for twice more than 2 hours and could use, followed by drying iron-clad, temperature controls at 200 degree for the first time, and second time controls at 165 degree&#;

4) mould: mould wants that first die trial is qualified could use, determines in passing and expects heavily&#;

5) the mixing of sizing material cuts: sizing material first passes through mixing test, vulcanization accelerator to be added when mixing, then by one Fixed material weight automatic cutoff&#;

6) vulcanizing/forming: vulcanizing/forming temperature and time to be controlled well, the fine temperature of general fourth controls at 200 degree, and the time is 120 seconds&#;The temperature of polyfluoroprene controls at 185 degree, and the time is 200 seconds&#;

7) rebuild and add spring: the deviation of trimming to be determined by the specification size of oil sealing, general small dimension is 0.15 ~ 0.2, big specification is 0.25 ~ 0.35, and it is fixed that spring specification is also that the specification according to oil sealing is come, and general spring specification to be remembered: line footpath * diameter * length&#;

Featured content:Hydraulic Vs Mechanical Boat Steering & A Guide to ...

Everything You Need To Know To Find The Best Auto coil spring lifespan factors

What's your opinions on liquid wraps? - BMW M3 Forum ...

10 Questions You Should to Know about Electric Scooter Tires for Sale Bulk Purchasing

Electric Scooter Tires and Road Safety

Ultimate Guide to Choosing Glossy Car Wrap Film: FAQs Answered

Key Considerations for Choosing the Perfect Brooklyn Grey Wrap

The company is the world’s best china oil seals supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

8) test package: check oil sealing external diameter to be surveyed, highly, (and R value, the outward appearance of oil sealing, the position particularly rebuild is smooth, and ferrum can not be seen in surface for secondary lip, internal diameter, trimming internal diameter.

The invention has the beneficial effects as follows: the present invention improves working (machining) efficiency, yield rate, reduce production cost, achieve the unforeseeable technique effect of those skilled in the art, overcome design set for a long time, provide a kind of new design and processing thought, and achieve more more preferable processing effect than prior art.

Detailed description of the invention

Technical scheme disclosed by the invention is a kind of oil sealing processing technology, it is characterised in that comprise the steps, 1) iron-clad returns factory's inspection&#;

2) epithelium: add degreaser and go fat &#; add Phosphating Solution to be processed on iron-clad surface, antirust &#; to add sulfuration liquid to increase iron-clad adhesive force&#;

3) then: soak in the iron-clad solid to be placed on of epithelium, as solid stock solution that acrylic, fourth are fine is the mixed solution of TD870 and ethanol, allocate in the ratio of 1:3.5, typically to soak at twice, iron-clad is put in people's stock solution, will stir for twice more than 2 hours and could use, followed by drying iron-clad, temperature controls at 200 degree for the first time, and second time controls at 165 degree&#;

4) mould: mould wants that first die trial is qualified could use, determines in passing and expects heavily&#;

5) the mixing of sizing material cuts: sizing material first passes through mixing test, vulcanization accelerator to be added when mixing, then by one Fixed material weight automatic cutoff&#;

6) vulcanizing/forming: vulcanizing/forming temperature and time to be controlled well, the fine temperature of general fourth controls at 200 degree, and the time is 120 seconds&#;The temperature of polyfluoroprene controls at 185 degree, and the time is 200 seconds&#;

7) rebuild and add spring: the deviation of trimming to be determined by the specification size of oil sealing, general small dimension is 0.15 ~ 0.2, big specification is 0.25 ~ 0.35, and it is fixed that spring specification is also that the specification according to oil sealing is come, and general spring specification to be remembered: line footpath * diameter * length&#;

8) test package: check oil sealing external diameter to be surveyed, highly, (and R value, the outward appearance of oil sealing, the position particularly rebuild is smooth, and ferrum can not be seen in surface for secondary lip, internal diameter, trimming internal diameter.

The present invention improves working (machining) efficiency, yield rate, reduce production cost, achieve the unforeseeable technique effect of those skilled in the art, overcome design set for a long time, provide a kind of new design and processing thought, and achieve more more preferable processing effect than prior art.

The preferred embodiment of the present invention described in detail above.Should be appreciated that those of ordinary skill in the art just can make many modifications and variations according to the design of the present invention without creative work.Therefore, all technical staff in the art, all should be in the protection domain being defined in the patent claims the most on the basis of existing technology by the available technical scheme of logical analysis, reasoning, or a limited experiment.

If you want to learn more, please visit our website nbr black cloth rubber oil seal manufacturers china.

Oil Seal Manufacturing Process - ASA OIL SEALS

Car Wrap Materials - A Complete Guide

How Does Matte Finish Car Paint Transform Appearances?

Key Factors to Consider When Choosing Sustainable Home Decor

What is a Cylinder Head and Its Function?

Commercial Vehicle Brake Pad Replacement: Step-by-Step Guide

Best Brake Pads for 2023: A Comprehensive Guide

Why Are Electric Motorcycles So Popular?

85

0

0

All Comments (0)

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments