Choose an electric wire rope hoist or an electric chain hoist ?

Feb. 26, 2024

Choose an electric wire rope hoist or an electric chain hoist ?

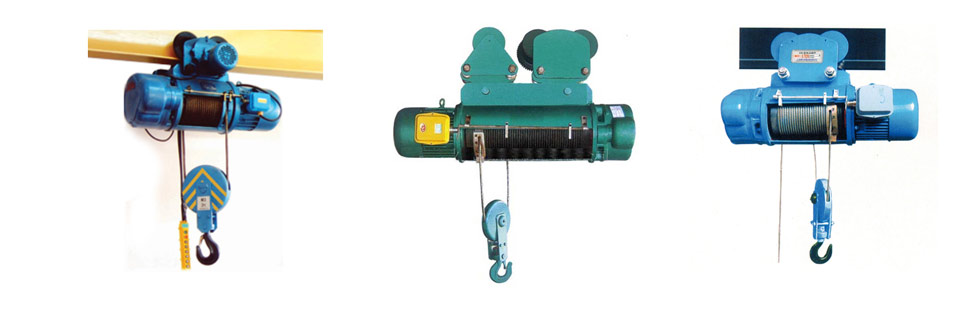

As a modern lifting equipment, electric hoists have been widely used in industry and manufacturing. Currently, there are two types of electric hoists commonly used on the market: chain electric hoists and wire rope electric hoists. How do you choose an electric hoist? Type is a problem faced by many customers now. We recommend choosing according to different usage conditions. First, we need to clarify the difference between the two:

1. The transmission media of the two are different. It is easy to understand according to their names. One transmission medium is a steel wire rope, and the other is a chain. The wire rope surrounds the drum and has a smaller diameter, so the working height is higher.

2. The two types of electric hoists have different operating speeds. Wire rope electric hoists are available at single-speed and double-speed. The speed is adjustable and fast. The electric chain hoist is relatively slow.

3. The operating conditions of the two are different. The wire rope electric hoist is suitable for lifting heavy objects or equipment with larger tonnage and faster lifting speed. An electric chain block hoist is suitable for lifting objects with small tonnage and slow lifting speed.

4. The wire rope electric hoist has a large load-bearing capacity. The equipment is usually used in large-scale lifting situations such as bridges, buildings, and steel plants. The weights lifted are heavy in tonnage and large in volume. The electric chain hoist has a fast lifting speed. The equipment is usually used in cargo stations, docks, warehouses, and other places, and can quickly and efficiently carry out heavy object lifting operations.

Compare chain hoist and wire rope electric hoist

1. Light weight. Compared with other types of hoist cranes, the dead weight of the chain hoist has been greatly reduced. This advantage makes the loading and unloading of the equipment more convenient. The placement of the equipment can be changed according to the needs of the actual operation, which increases the number of lifting operations. Flexibility, and adaptability to various working situations.

2. Small size. For electric hoists of the same tonnage, the volume of electric chain block hoists is several times or even dozens of times smaller than that of wire rope hoists;

As the name suggests, the electric chain hoist is driven by a chain, and the separation of the chain bag from the hoist main machine is a major advantage. It overcomes the problem of the large volume of the wire rope electric hoist drum, so in terms of volume, the chain hoist is smaller than the wire rope hoist crane. The higher the lifting height, the larger the volume of the electric wire rope hoist is than that of the chain hoist. Because the wire rope of the wire cable hoist is wound on the drum, it has a greater impact on the volume.

3. Higher lifting height. For tracks of the same height, the height of an electric chain hoist is much higher than that of a wire rope hoist crane;

The wire rope of the electric wire rope hoist for lifting height is wrapped around the drum, resulting in elastic deformation. The side of the drum is subject to pressure, and its corresponding surface is subject to tension. The smaller the diameter of the drum, the greater the deformation of the wire rope. The corresponding surface of the wire rope the greater the pressure and tension. In order to prevent this pair of forces from exceeding the bearing capacity of the wire rope, the diameter of the drum must be larger so that the deformation of the wire rope will not be too large.

The connection of the electric chain block hoist is the hinge between the chain links, and the main force the chain bears is the pulling force.

As a result, the lifting height of an orbital chain electric hoist of the same height is higher than that of a wire rope electric hoist.

4. Under the same track length, the running distance of the electric chain hoist is longer than the running distance of the wire rope;

5. The positioning of the chain hoist hook is more accurate than that of the wire rope hoist;

When the wire rope electric hoist is lifted since the wire rope is arranged and wound on the drum in an axial direction, the hook will move horizontally along the axis of the electric hoist. The greater the lifting height, the more turns the wire rope is wound on the drum, and the greater the horizontal displacement of the hook. No matter the lifting height of the electric chain hoist, the hook will go up and down along the plumb line of the chain, that is, the hook of the electric chain hoist can be accurately positioned.

6. Electric chain hoists are more convenient to install than wire cable hoists;

7. The chain hoist's ability to handle diagonal pulls is better than that of the wire cable hoist;

According to the relevant technical specifications, the electric hoist should be in a vertical or horizontal state during use to avoid the situation of diagonal pulling of heavy objects. However, in practical applications, the diagonal pulling of electric hoists is unavoidable. The difference between the wire rope electric hoist and the running trolley the connection method between the two wire rope hoists is rigid, and it is easy to cause damage to the rope guide when the oblique pull force is too large. If the device fails to stop operation in time, it may cause the motor to rupture, resulting in damage to the entire wire rope electric hoist. For this reason, generally, the manufacturer will clearly stipulate in the product manual that the inclination angle of the wire rope electric hoist to the rope groove must be within the range of 3.5 degrees.

8. The chain block hoist will not have the "rope tangle" phenomenon like the wire rope hoist crane, and the failure rate is low;

The winding device of the wire rope electric hoist is a steel wire, which itself has a certain degree of rigidity. It is prone to the phenomenon of troughing when no load is used. This situation is more likely to occur when a small weight is lifted or heavy objects are transported outside the support, resulting in rope chaos. Question. The winding device of the chain hoist is a chain, and the winding method is hinged. It has no rigidity and the above phenomenon will not occur.

9. The service life of the chain hoist is longer than that of the wire rope electric hoist.

The steel wires equipped with wire rope electric hoists are often relatively thin, and the lifting equipment itself may work in extreme environmental conditions, such as moisture, acid mist, and high temperatures. In this case, the thin steel wires are prone to breakage, shortening the use of the wire rope. The service life may also lead to safety accidents. However, the cross-section of the chain hoist steel wire is relatively large, and its core material is often selected to be high temperature resistant and anti-oxidation type, which is not prone to major changes in harsh environments.

10. The electric chain hoist is easy to modify. The modification of the chain hoist is very convenient and has nothing to do with the lifting height. Different chain block hoist models have the same design. During modification, you only need to change the length of the chain. Professional technicians can also directly weld the short chain. Extended measures, this design is very simple to operate. In contrast, the model of the wire rope electric hoist is closely related to the lifting height, and it cannot be modified as easily as the former. If the lifting height changes, the corresponding model will be idle and wasted, which will increase the amount of depreciation.

If you have different opinions on wire rope electric hoists and chain electric hoists, please contact us.

104

0

0

All Comments (0)

Previous: How to choose the Right Rigging Equipment for your Project

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments