What is color coated steel coil and how are the different coatings manufactured?

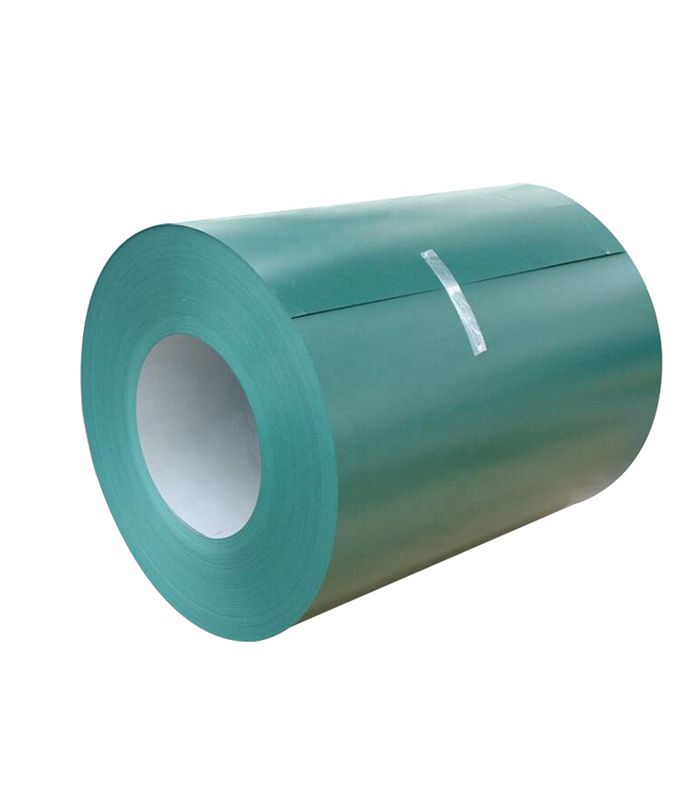

Color-coated steel coil also known as pre-painted steel coil, is a type of steel coil that has been coated with a layer of paint or protective coating on its surface. The coating not only enhances the appearance of the steel but also provides protection against corrosion and other environmental factors, making it suitable for various applications in construction, automotive, and appliances industries.

Manufacturing Process of Color Coated Steel Coil:

The manufacturing process of color-coated steel coil involves several steps to ensure a uniform and durable coating. The process generally includes the following stages:

1. Surface Preparation:

The steel coil is first cleaned and prepared to ensure proper adhesion of the coating. The surface is cleaned of any contaminants, oil, or rust, and then it may undergo chemical treatment to enhance its bonding characteristics.

2. Application of Primer:

A primer layer is applied to the surface of the steel coil. The primer helps in promoting adhesion between the steel surface and the subsequent layers of paint or coating.

3. Coating Application:

After the primer, one or more layers of colored paint or coating are applied to the steel coil. The type and number of coating layers depend on the specific requirements of the final product and the level of protection needed. The coatings can be made from various materials, including polyester, polyvinylidene fluoride (PVDF), polyurethane, epoxy, and others.

4. Curing and Drying:

After the coating application, the steel coil is subjected to a curing process, where it is heated to a specific temperature to allow the paint or coating to chemically bond and dry onto the surface. This curing process ensures the formation of a strong and durable coating.

5. Cooling and Inspection:

Once the curing is complete, the coated steel coil is cooled down to room temperature. It then undergoes thorough inspection for quality control, checking for any imperfections or defects in the coating.

Advantages of Color Coated Steel Coil:

Enhanced Aesthetics: Color-coated steel coil offers a wide range of colors and finishes, enhancing the aesthetics of the final product. It allows designers and architects to create visually appealing structures and products.

Corrosion Resistance: The protective coating on the steel coil provides excellent corrosion resistance, making it suitable for outdoor applications and environments with high humidity or salt exposure.

Durability: Color-coated steel coils are designed to withstand harsh weather conditions, UV radiation, and mechanical stress, ensuring the longevity of the product.

Cost-Effectiveness: By using color-coated steel coils, manufacturers can avoid the need for additional painting or finishing processes, saving time and costs in the production.

Versatility: Color-coated steel coils can be used for a wide range of applications, including roofing, cladding, garage doors, appliances, and more.

In conclusion, color-coated steel coil is a steel product coated with a layer of paint or protective coating to enhance its appearance and provide protection against corrosion and environmental factors. The manufacturing process involves surface preparation, application of primer and coating, curing, cooling, and inspection. The wide range of available colors and finishes, along with the advantages of durability, corrosion resistance, and cost-effectiveness, make color-coated steel coil a popular choice in various industries.

176

0

0

All Comments (0)

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments