Benefits and Applications of Conveyor LBP Chain

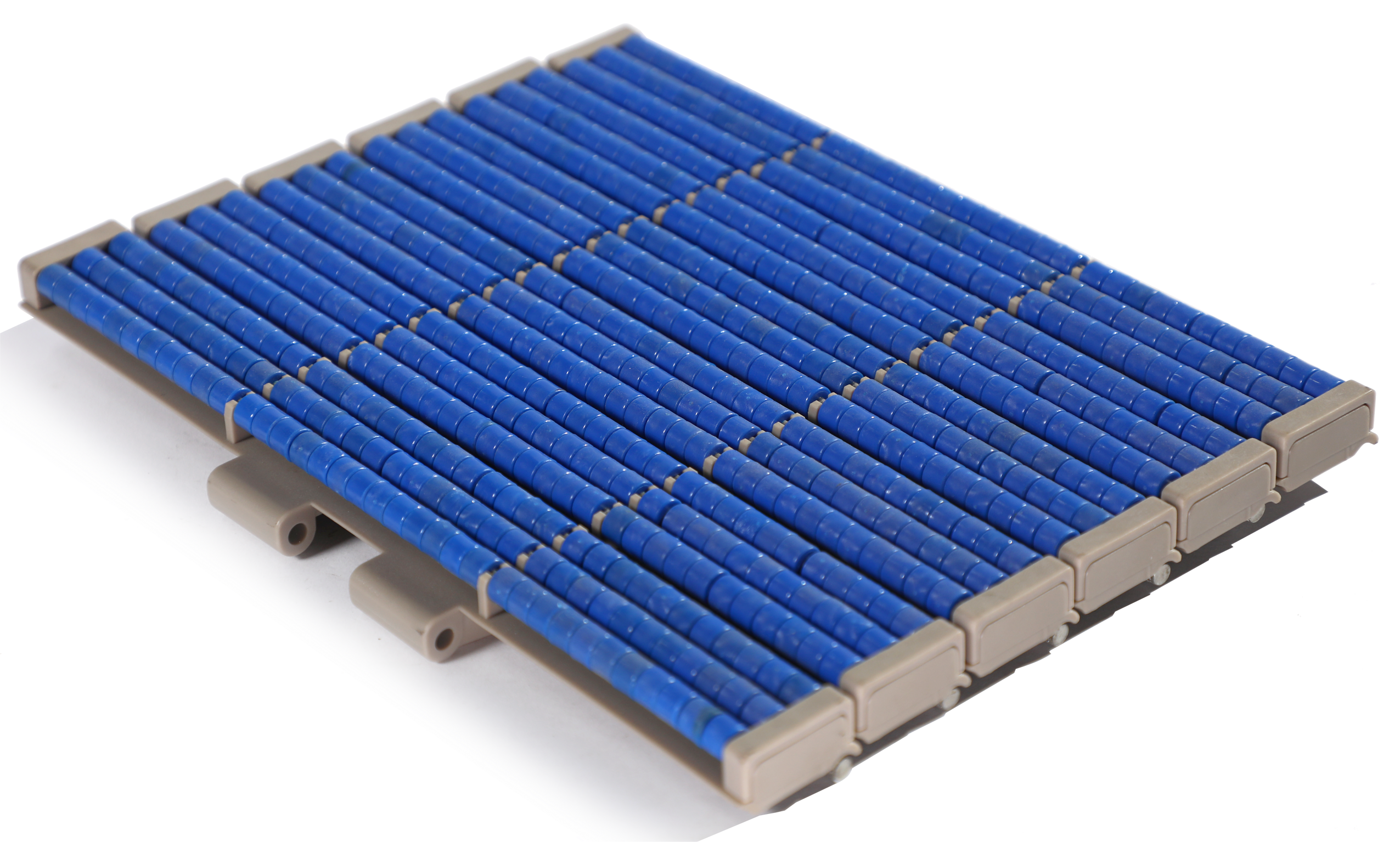

Conveyor LBP chains are innovative components designed to improve material handling efficiency in various industries. These specialized chains reduce back pressure, ensuring smooth and consistent movement of goods, even in high-speed operations.

Key Features of Conveyor LBP Chain

Low Back Pressure Technology

The LBP chain minimizes friction between products during transportation. This feature is crucial in preventing damage and ensuring smooth operations.

Durable Construction

Made from high-quality materials, LBP chains are built to handle heavy loads and withstand wear and tear. Their robust design ensures long-lasting performance.

Modular Design

The modular structure of LBP chains allows for easy customization and integration into existing conveyor systems.

Enhanced Product Stability

These chains are designed to provide maximum stability, preventing products from tipping or shifting during transport.

Applications of Conveyor LBP Chain

Food and Beverage Industry

LBP chains are widely used in the food and beverage sector. They ensure seamless movement of bottles, cans, and other products, reducing downtime and increasing productivity.

Pharmaceutical Industry

In pharmaceutical manufacturing, these chains are ideal for transporting delicate items, ensuring precision and care in handling.

Featured content:How Samsung AC Servo Driver Transforms Automation Today?

Automotive Industry

LBP chains streamline the movement of parts in automotive assembly lines, optimizing efficiency and maintaining workflow consistency.

Packaging Industry

They are perfect for packaging lines, allowing smooth transport of boxes and cartons without product damage.

Benefits of Using Conveyor LBP Chain

Reduced Maintenance Costs

The durable design of Radius LBP chains minimizes wear and tear, reducing the need for frequent maintenance or replacements.

Improved Operational Efficiency

With low back pressure and enhanced stability, LBP chains ensure a smoother workflow and faster processing times.

Versatile Applications

From food processing to heavy industries, these chains adapt seamlessly to diverse operational needs.

Product Safety

By reducing back pressure, LBP chains protect products from damage, ensuring quality standards are maintained.

Conclusion

Conveyor LBP chains are an essential component for efficient material handling in various industries. Their advanced features, durability, and versatility make them a valuable investment for improving productivity and product safety. By integrating LBP chains into your operations, you can achieve smoother workflows and enhanced efficiency.

47

0

0

All Comments (0)

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments