The best garden loppers tried and tested

Jun. 10, 2024

The best garden loppers tried and tested

Essentially supersized secateurs on long handles, garden loppers are invaluable for tackling thick or out of reach branches. But choosing the right pair can be a minefield since they vary so much in weight, size and performance.

If you are looking for more details, kindly visit Tree-Grip Dead Ends.

Like secateurs, loppers come with different cutting actions and the one you choose depends on the sort of work you need them for. For everyday use, you'll want a pair of bypass loppers. These cut with a scissor action, with one blade crossing over the other. They tend to be the lightest so are good if you struggle with heavy tools or need to do a long session of pruning without your arms getting tired. They cut beautifully through green, living wood in a slicing motion.

For dead or brown wood, a pair of lightweight loppers with an anvil cutting action is the one to go for. These also handle living wood so are a good all rounder. With an anvil model, a blade presses down onto a curved anvil, crushing the wood inbetween the blades.

For thicker branches you need a more heavyweight pair of loppers with a geared or ratchet blade mechanism. These increase the power of the cut, taking the effort out and making short work even of branches you'd normally tackle with a pruning saw. The mechanics at the head end make these loppers relatively top-heavy so they're best for really hefty jobs or shorter bursts of pruning.

For really high branches, consider a pair with extendable or telescopic handles. These are easy to operate and will extend your reach to almost a metre. The material of the handles can make a difference too. Wooden handles feel warm and comfortable while tubular aluminium or plastic is the lightest.

An important distinction between loppers is the impact they put on the arms when you snap the blades together. If there's a hard jolt every time you close them it can lead to aches and pains so look for a rubber buffer between them for a soft finish.

We tested 10 leading garden loppers on a variety of garden shrubs and trees from willow to damson, eucalyptus, hazel to ornamental grasses. We considered their cutting performance, comfort, aesthetic appeal and value.

Bulldog Compound Bypass Lopping Shears

Best everyday garden loppers

If you only buy one pair of garden loppers, you could do a lot worse than this bypass pair which weigh under a kilogram. With tubular aluminium handles and a small, cutting head, they feel particularly lightweight at the top end making them comfortable on the forearms and wrists to use for long periods. At 73cm long, their handles are relatively long for bypass loppers and this gives you powerful leverage for the cut. The blade is sharp enough to manage surprisingly thick stems (it advertises as coping with up to 3.8cm diameter) and branches with no trouble at all thanks to its compound cutting action.

We like: the large chunky grips at the bottom of the handles

RRP

£42.11

Available from Thompson & Morgan

Shop NowDarlac Heavy Duty Geared Lopper

Best for seriously thick branches

These quite serious looking loppers have an unusual vertical cutting action with a curved upper hook to grab onto branches (or thick roots?) and then a 5mm blade that cuts down like a guillotine. We were astounded at how easily this managed thick branches 5cm in diameter, cutting through eucalyptus and dead damson tree wood without much effort on the arms at all. It made us all feel quite bionic, its extra power thanks to the heavy duty rack and pinion geared cutting action. Though the aluminium handles are lightweight, the chrome plated steel head makes them quite top heavy (the whole thing weighs in at just over 1.5kg) so these are best for using in short bursts, when you want to tackle really hefty branches.

We like: their power

RRP

£47.95

Available from Amazon

Shop NowGardena Supercut All Purpose Loppers

Most comfortable loppers

Of all the loppers we tested these were the ones I couldn't wrench off my 75 year old mother. Weighing only 620g she found this German-made bypass model so light and easy to use she was coppicing the willow at lightning speed. The chunky glass-fibre reinforced plastic handles are fairly short making them easy to manoevure, though not ideal for high branches, while an innovative gear mechanism gives the cutting action twice the power so they can manage stems up to 3.5cm diameter. Shock absorbers between the handles give them a nice soft-close finish, protecting the wrists from impact. They also come in a Hardwood version which have an anvil cutting action.

We like: how easy these were on the wrists

RRP

£29.95

Available from FFX UK

Shop NowBurgon and Ball Ratchet Lopper RHS Endorsed

Best telescopic loppers

These have telescopic handles that extend to 80cm so are great for really tall branches. They have a powerful, large ratchet mechanism to handle large branches and an anvil cutting action so can manage dead as well as living wood. We found it cut very well, the ratchet mechanism taking the strain as it cut through thick branches of dead wood up to 4cm in diameter in a series of five stages. Though the blades are straight, there's a curved portion at the tip to grab onto branches. When the handle are fully extended the leverage power is even greater.

We like: that it can handle both living and dead wood

RRP

£48.99

Available from Burgon & Ball

Shop NowSpear and Jackson Razorsharp Advantage Telescopic Ratchet Bypass Loppers

Best for tree pruning

I've had a pair of these heavy duty ratchet loppers for several months now and they've cut through hundreds of hazel branches and suckers with no trouble so I can't fault them. They've also been thrown around in the boot of the car so proved their resilience. The telescopic handles extend up to 80cm by twisting the ends of the handles so you can reach high branches. If used for longer periods they are easiest on the wrists used unextended. The ratchet takes the strain as you cut through wood up to 4.2cm In diameter with a sharp carbon steel blade.

We like: their reliability

RRP

£23.98

Available from Argos

Shop NowWilkinson Sword Ultralight Bypass Loppers

Best lightweight loppers

These are by far the lightest of all the loppers tested, weighing only 450g. You can carry them around with one hand and lop away for ages without getting tired. The curved bypass cutting head is small and light so it's easy to get it into the right position for cutting each stem, speeding up the whole pruning process. Their weight and precision would make them ideal for tackling fruit tree suckers or bamboo when you are leaning down but they would be just as good with overhead pruning. These loppers would be ideal for anyone who struggles with heavy tools or who does a lot of lopping of stems and branches up to 2.5cm in diameter.

We like: the non-slip grips are particularly nice to hold

RRP

£30.43

Available from Amazon

Shop NowNiwaki Loppers

Best for shrubs and topiary

These very stylish-looking pair of loppers made in Japan have a carbon steel head and beautiful white oak handles that are a pleasure to handle. The bypass blade is robustly made with a shiny sharp cutting blade crossing over a matt black lower blade. The weighting is good and the wooden handles have a bit of flex in them as well to absorb the impact when you cut. They can cut branches up to 2.5cm in diameter though thicker wood should be cut at a 45 degree angle. With their relatively short handles and shallow curved cutting head we found these particularly excelled when pruning shrubs, large grasses or topiary. As with all Niwaki products, these arrived in a beautiful cotton drawstring bag.

We like: the high-end Japanese design

RRP

£99

Available from Niwaki

Shop NowArs Professional Lopping Shears LPB-30M

Best for professionals

Ars (which stands for 'Always Really Sharp') is a Japanese made brand of cutting tools aimed at professionals. These sleek black, silver and red bypass loppers have 63cm long tubular aluminium handles, matt plastic non-slip grips and, of course, extremely sharp high carbon steel blades. The lower blade even has a metal 'step' halfway down to strengthen and stabilise it. The closing action is a little on the snappy side, but this is a great pair of loppers ' lightweight (975g), well-balanced and able to handle living wood up to 3.6cm. Ars has a good spares department too, if necessary, so these should last you a long time.

We like: the no-nonsense efficiency

RRP

£71.95

Available from Amazon

Shop NowSophie Conran for Burgon & Ball Lopper

Best for traditionalists

The combination of chunky carbon steel and graceful ash handles make these loppers perhaps the most elegant looking on trial, and certainly the best suited to be teamed with a straw hat. Interior designer Sophie Conran's range of garden tools always combine grace with efficiency and these are lovely to hold, the 70cm long handles moulded to give a particularly comfortable grip. At g, these are not the lightest bypass loppers around but that's down to the beautifully curved large drop forged carbon steel blades which effortlessly slice through living wood up to 2.5cm diameter.

We like: the ergonomic ash handles

RRP

£38.99

Available from Sophie Conran

Shop NowAlpen Weisshorn 260 Loppers

Best new loppers

From the sister company of Felco comes Alpen, a new range with a lighter price tag but still featuring the performance and precision we've come to expect from the Swiss brand. Rather than the trademark Felco red, Alpen's new range of tools come in a striking black and warm tangerine. These 975g bypass loppers have nice squidgy hand grips and a generous double shock absorber. The curved blade is hardened carbon steel and the 60cm handles tubular aluminium making them feel light and well balanced. Effective and comfortable to use even for long periods, cutting through wood up to 3.5cm in diameter.

We like: these are really comfortable to use

Featured content:XLPE Cable and Frequently Asked Questions

Best smart light switches in 2024

Ultimate Guide to Metallic Fittings: Everything You Need to Know EU

What are the disadvantages of flexible metal conduit?

Discover the Crucial Benefits of ATEX Flexible Metal Conduit

Corrugated Conduit Hot Sale: Everything You Need to Know About the Latest Must-Have Trend in Cable Management!

Ultimate Guide to Flexible Metal Conduit Low Fire Hazard

Want more information on Distribution Grip Dead End Manufacturer? Feel free to contact us.

RRP

£49.99

Available from Alpen

Shop NowTips and Best Practices for Using Lowering Devices

There are a number of lowering devices designed for tree rigging available on the market today. In this article, we'll look at best practices for using lowering devices in general and at specific tips for using three of the most commonly used devices, the Port-A-Wrap, the Good Rigging Control System (GRCS) and the Hobbs H-2.

The Port-A-Wrap is a portable, rope-friction device used to lower loads that a single ground person could not lower alone without additional friction. It was co-invented by Scott Prophett and Norm Hall. Buckingham Manufacturing makes it; Notch Equipment also sells a version, as does Bailey's.

Here are some pointers from Norm Hall for use of the Port-A-Wrap. Hall has been working for more than 45 years in the tree care industry. He currently works at All Gear, Inc., as a splicer and trainer. He is also the lead instructor for the Illinois Arborist Association Advanced Training program's 'Tree Worker' domain.

Port-A-Wrap best practices

By Norm Hall

The Port-A-Wrap, commonly called the porty, is manufactured in four different sizes and will accept rope diameters from ½-inch to 7/8-of-an-inch, depending on the model. The device is mounted near the base of a tree using a rope sling. Different sling versions can be used, such as a spliced-eye, whoopie or loopie, but my preference is a spliced-eye sling. I prefer a spliced-eye sling because the throat distance can be minimized, keeping the device on the trunk right where it is mounted. If the device is anchored using a whoopie or loopie sling, it can spin the sling once loaded.

The Port-A-Wrap was invented to eliminate taking rope wraps on the tree trunk. This process involved coiling the lowering rope to take the appropriate number of wraps on the trunk, lowering the load, then coiling the rope again to unwrap it. The amount of friction was determined by the bark of the host tree. As arborists, we know that not all bark is the same, so the ground person had to be familiar with the various tree species in the area to be an effective lowering person. The Port-A-Wrap eliminates that problem, providing a constant amount of rope friction every time. There is no guesswork.

Here are a few tips for safely using a Port-A-Wrap.

' Always read the manufacturer's instructions before using any tool or piece of equipment.

' Before anchoring the porty, figure out where the lowering rope is going to be anchored and mount the porty near the base, where there will be minimal limb interference with lowering rope.

' The Port-A-Wrap is mounted near the base of a tree around knee height. To anchor, I prefer to use a cow hitch, but when the sling isn't long enough to go around the host tree twice, I use a timber hitch.

Note: Do not add a link to the long loop to anchor a sling (Photo 1).

' While tying either hitch, it's important to leave the throat length as short as possible. Leaving a short throat is important during negative-rigging operations. This is because, as the log section falls, the Port-A-Wrap inverts and drops the same distance as the 'fall' of the rigging rope. The shorter the throat length, the less shock (dynamic) loading there is on the porty and anchoring sling.

Tying proper hitches

Here are a few notes about tying the cow hitch and timber hitch properly.

The cow hitch starts as a girth hitch tied with the end of the rope, but is secured with a half hitch. The proper way to finish has the half-hitch tail exiting toward the bight of the hitch. Any excess tail can be tucked under either one of the sling legs, capturing the bight. (Photo 2)

Photo 2: This image (left) shows a small Port-A-Wrap and a large Port-A-Wrap, each tied with a cow hitch. The yellow rope (top porty) tail goes toward the inside of the bight, which is the incorrect method of finishing a cow hitch. The red rope (bottom porty) tail goes toward the outside of the bight, which is the correct way to tie a cow hitch. The excess tail can be tucked under one of the sling wraps, capturing the device. A limitation to tying the cow hitch is that there must be enough tail length to go around the host tree twice and then tie a better half hitch around the throat. NOTE: The Port-A-Wrap must be tied with as short a throat length as possible, especially during negative-rigging operations.When tying a timber hitch, we have two choices of making our five tucks. After the bight is formed, we can start our spiral tucks from the top or bottom. (Photos 3 & 4) Starting from the top will 'add' tucks if the sling should roll up the spar during the lowering operation. Tucking from the bottom will 'subtract' tucks should the sling roll up. (Photo 5)

Photo 3: If there isn't enough sling length to tie a cow hitch, a timber hitch can be tied. When the device is anchored near the base of a tree, the tucks must be started on the top of the sling (Photo 4, below). A minimum of five tucks is required.Photo 4: The timber hitch works on the bark contact of the tucks on the inside spirals (red arrows). When tying a timber hitch, spread the tucks out to make spirals rather than turns. Photo 5, 1-3: Starting the tucks on the bottom of the sling can result in the tucks becoming undone if the sling rolls up the trunk, as illustrated in these images. 1: Starting underneath. 2: Five tucks completed. 3: The sling rolled up the trunk once loaded, resulting in losing two tucks.Another consideration for the timber hitch is the direction in which it is loaded. The timber hitch works best when it is loaded against the bight of the hitch. When loaded against the bight, it puts force on the tucks, helping prevent movement. Loading with the bight will not let this occur. The sling can spin, and in some instances the tucks become turns instead of spirals, lessening bark contact and the effectiveness of the hitch.

I have found that by adding a turn on the throat, creating a round turn, it lessens rope creep at the throat, plus it increases the radius bend at the throat. I call it the 'better timber hitch.' Five tucks are still required for the improved version. (Photo 6)

Photo 6: An improved version of the timber hitch takes a 'round turn' at the throat. I call it 'the better timber hitch.' I find that the sling doesn't creep as much tied in this fashion. A minimum number of five tucks is still required.Ready to use

Once the device is anchored to the host tree, it's ready to use. When the device is in its 'at-rest' position, it is inverted. To install the lowering rope, grab it, position it upright, install a bight of the lowering rope through the angled loop and capture the bight of rope under the retention pin. (Photo 7) For heavier loads, additional wraps are needed. Make sure to wrap the lowering rope in the same direction as the bight install. (Photo 8) Taking wraps in the opposite direction will twist the rope, plus it makes a tight radius bend, which is not rope friendly. (Photo 9) The heavier the load, the more wraps are needed. Rarely are more than three wraps required. No different than any other lowering operation, always keep the excess rope in front of you, not behind you.

Photo 7: To use the Port-A-Wrap, take a bight of rope and go through the short, 'angled' loop and capture the rope underneath the retention bar. Photo 8: For heavier loads, wrap the lowering rope around the long leg in a spiral fashion, going in the same direction. Photo 9: This is the incorrect way to load the device. Notice the rope goes through the angled loop and is wrapped in the opposite direction on the long leg. Wrapping the rope in this fashion can cause twisting in the lowering rope, not to mention the tight radius bend.The long leg pins serve dual purposes. They prevent the lowering rope from sliding off the end, and they work as

lowering-rope cleat pins. If a lowered limb needs to be cut into smaller sections before being lowered to the ground, the ground person can take as many wraps as possible on the long leg and tie a half hitch around the long pin. The lowering rope must stay in contact with the round tube and away from the sharp edge. (Photo 10)

During negative-rigging operations, it's important to have the lowering rope exit off the lower pin of the long leg. This is what happens during a negative-rigging operation; the log falls and the Port-A-Wrap drops the distance of the fall of the rope, creating slack in the lowering rope. The lowering rope is captured by the lower pin leg. If the lowering rope exits off the top pin, as the porty drops, the lowering rope can come off the lower pin, resulting in loss of friction. (Photo 11) I have witnessed this happen. Photo 11, 1-3: During negative-rigging operations, if the lowering rope exits off the top leg pin, the lowering rope may lose the additional ½ wrap, resulting in less friction.

The Good Rigging Control System (GRCS)

The Good Rigging Control System, or GRCS, is a friction-control device used in lifting or lowering trees or tree parts. It was invented in by Greg Good, owner of Good Tree Care Company, a 27-year TCIA member company based in Hartland, Wisconsin, when he had the idea of using a yacht winch for tree rigging. It is manufactured by Good Rigging, LLC.

Pointers on using GRCS

By Greg Good

Every rigging situation an arborist deals with is also an engineering problem. We built our first winch system to solve a tree-removal problem that called for a crane, except the job site was inaccessible to one. More than a lowering device, the GRCS has been called a 'crane in a box' by many users. Its built-in mechanical advantage gives arborists real power to apply to rigging situations.

GRCS: Always place rope through the upper fairlead (opposed 'L' hooks) at top of mount and wrap rope clockwise around winch drum, beginning on the inside of the drum. Continue wrapping without overlap until no more wraps can fit. Photo by Greg Good.All rigging operations need to begin with a thorough assessment of the trees to be worked on, followed by a rigging plan. We use a basic model for all of our rigging operations. Beginning with the size of the piece we wish to remove, we ask the following questions:

A. Is the rigging point sufficient to handle the load?

B. Which rigging technique will work best?

C. Do we have the equipment needed, sized and rated to handle this load?

D. Have we installed the equipment properly, and do we understand how to use it?

E. Do we know which cutting technique we need to use?

F. If we take a piece this size, will the ground crew be able to handle it and land it safely?

G. Does everyone on the crew know what is going to happen and what their job is?

If there is any doubt about any question of the model, we don't make the cut. You can always go back to the beginning and make the necessary changes. Remember, you can always take a smaller piece.

GRCS: A drill motor can be used to drive the winch when used with the drill adapter. Photo by Greg Good.The thing I tell people who get their first GRCS is to use it frequently, starting with simple rigging scenarios to get familiar with properly setting it up and operating it. The GRCS is designed to be simple and safe to use, but training is necessary. If you want to play a guitar, picking it up every six months won't get you too far.

GRCS: It is important to have the rope pulled slightly away from the outer end of the pigtail to prevent the rope from overwrapping while lowering. Photo by Greg Good.A GRCS is a significant investment, and many companies purchase one when they have sold a job they feel can't be done without one. This can mean that someone may be attempting to apply an unfamiliar tool to a tough problem. Take time to get familiar with the device.

GRCS: Grip rope firmly, always keeping it under tension. Begin unwrapping rope from the groove of the self tailer. Photo by Greg Good.Watch the instructional video and understand the basic setup of the device. Understand that the rope fairleads must be used when lifting and lowering to make it safe and efficient, and they must be used every time. Watch the 'Safety First' section of the video.

Use best practices with your GRCS:

' Don't set up your GRCS directly under the rigging point; if the rigging point changes, move your GRCS out from under it.

' Remove the winch from the mount during setup and storage. Remove the winch from the mount when the climber is going to cut pieces and let them fall to the ground, i.e., as in cutting and dropping a branch stub after a large limb has been removed.

' Fold the pigtails down when not in use. Remove the winch handle before lowering operations.

' Always use the fairleads as shown in the instructions.

Tips for using the Hobbs H-2 and other lowering devices

The Hobbs lowering device was first designed and manufactured in by Ed Hobbs, and has been improved and redesigned over the years by Ken Johnson, according to a history of the device on the Bailey's arborist supplies website. Bailey's, a 30-year TCIA corporate member company based in Woodland, California, is a distributor of the Hobbs H-2, the latest iteration of the original.

The H-2 is designed for lowering lines from ½-inch to ¾-inch diameter, and has a working load limit (WLL) of up to 3,000 pounds. The H-2 has a lifting capacity of 1,000 pounds. The heart of the device is the aluminum spool, which is designed for extreme impact loading, wear resistance and heat dissipation. It's mounted on a 1-1/2-inch, solid-steel shaft, with oil-impregnated bushings. The H-2 comes complete with a 20-foot mounting strap (fitting trees up to 6 feet in diameter), winch bar and detailed graphics explaining proper usage, ratings, warnings and safe operations.

Alan Precup, industrial sales representative with Bailey's, provided the following tips for using the Hobbs H-2 and other lowering devices.

Overall

' Be sure to use rigging tools that are compatible with each other and are well within the WLL of the logs/branches you are lowering. WLL is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield. The WLL is calculated by dividing the minimum breaking load (MBL) by a safety factor (SF).

' Keep the work area clear of branches and debris.

' Have drop-zone cones for additional safety and awareness.

' Inspect your rigging lines and slings regularly.

Port-A-Wrap (ArborMax)

' Make sure the rigging line is tight (sweating the line) before adding friction wraps.

' When negative rigging, let it run! (to dissipate the energy of impact and reduce the shock/impact on the tree and/or climber).

Advantages

' Simple and easy to use.

' Great for negative rigging.

' Reduces wear on rope.

' Low cost.

Disadvantages

' Cannot lift.

' Not fully attached to the tree; inverts when not under tension.

GRCS/Hobbs

' Limited ability to absorb impact/shock in negative-rigging applications. (GRCS more than Hobbs*).

' Allow for pre-tensioning the lowering line.

' Can lift the load/branch (GRCS, which has two gear settings for up to 3,000 pounds of lift.)

Advantages

' Greatly reduced potential for damage.

' Fully attached to base of the tree.

' Reduces wear on rope.

' Eliminates any shock or drop in rigging system.

Disadvantages

' More difficult to set up.

' Higher price.

Conclusion

Each type of lowering device has advantages and disadvantages, and which one to use for any one job will depend on the situation. Evaluate the needs, consider the options, then, as Greg Good advises, practice, practice, practice.

The heart of the Hobbs H-2 is the aluminum spool, which is designed for extreme impact loading, wear resistance and heat dissipation. Photo courtesy of Bailey's.* Per Greg Good: 'We don't recommend using the winch component of the GRCS in extreme negative-rigging situations, but it has been tested in negative-rigging situations where a ¾-inch lowering line (20,000-pound tensile) repeatedly failed with no damage to the winch. The GRCS includes the interchangeable aluminum bollard, which can be used when extreme shock loading is expected. The aluminum bollard has been static tested to more than 40,000 pounds and is designed to allow the installation of an ice pack to help prevent heat damage to ropes.

'While the GRCS winch is rated for a dead pull of 2,950 pounds, we rated the maximum lift at 2,000 pounds, therefore not exceeding the safe-working-load limit of the ¾-inch-diameter lowering line, which is the largest rope recommended for the GRCS while using the winch component.

'With the bollard installed, lowering-line rope diameter is not limited.'

The company is the world’s best Distribution Grip Dead End supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Is Flexible Metal Conduit the Key for Water-Proofing Your EU Gadgets?

Exploring the Benefits of Interlocked Gal Flex

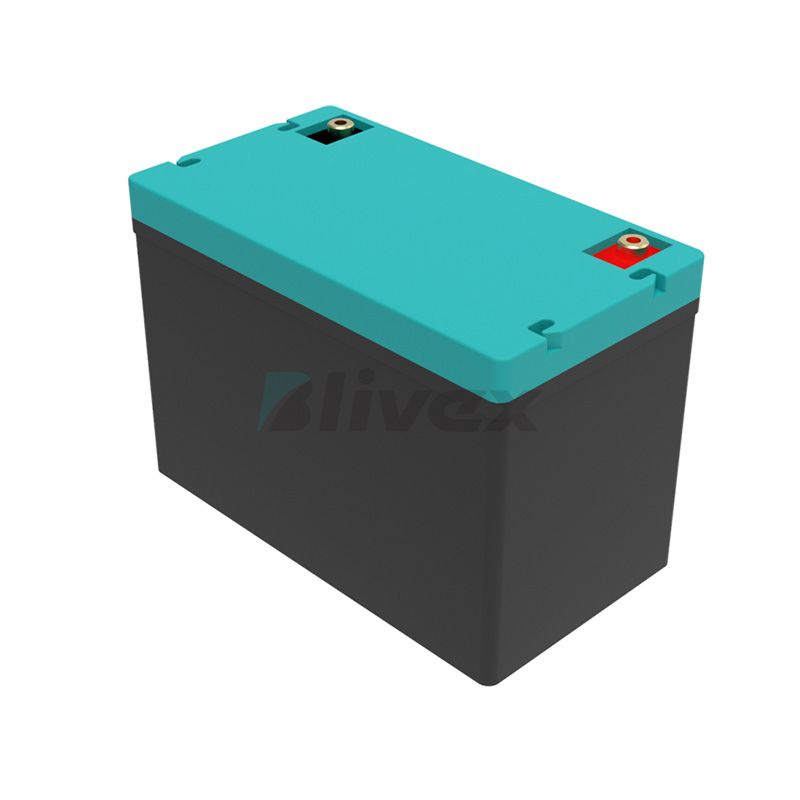

Applications of Low-Voltage Lithium Battery

Understanding the Benefits of Solar Emergency Charging Lamps

The Shared Power Bank: Empowering Your Mobile Lifestyle

What Are the Benefits of Using an Electric Under Blanket for a Restful and Warm Night's Sleep?

Surface Mount Package Sizes

111

0

0

All Comments (0)

Previous: How to properly use cable clamps?

Next: 10 Questions You Should Know about Properties of a Good Insulator

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments