How durable is UHMWPE marine fender face panel?

Jun. 10, 2024

Link to kenuo

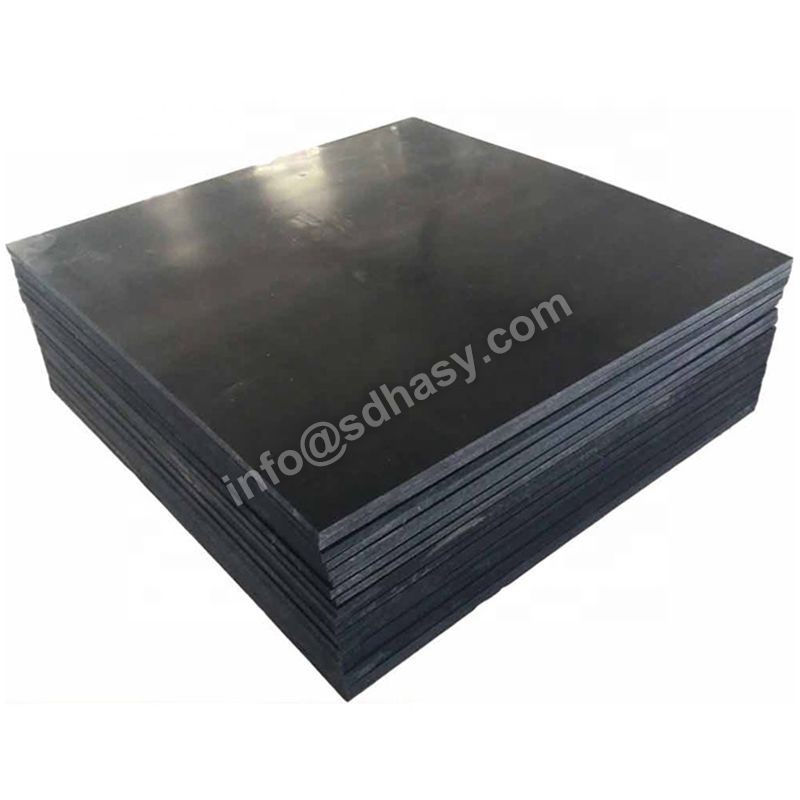

When it comes to marine fenders, one of the most important components is the face panel. This is the part of the fender that comes into direct contact with vessels, protecting them from damage and ensuring safe berthing. One material that is commonly used for marine fender face panels is Ultra High Molecular Weight Polyethylene (UHMWPE). But how durable is UHMWPE as a material for marine fenders? Let's delve into this question and explore the various factors that contribute to its durability.

UHMWPE is a type of polyethylene that has extremely long chains of molecules, giving it high strength and wear resistance. This makes it an ideal material for marine fender face panels, as it can withstand the harsh conditions of marine environments. One of the key factors that contribute to the durability of UHMWPE is its ability to absorb impact energy. When a vessel comes into contact with a fender face panel made of UHMWPE, the material is able to dissipate the energy of the impact, reducing the risk of damage to both the vessel and the fender itself.

Another factor that contributes to the durability of UHMWPE marine fender face panelUHMWPE marine fender face panels is its resistance to abrasion. In a marine environment, fender face panels are constantly subjected to abrasion from the movement of vessels against them. UHMWPE is highly resistant to abrasion, which helps to prolong the life of the fender face panel and ensure its continued effectiveness in protecting vessels.

In addition to its impact resistance and abrasion resistance, UHMWPE is also highly resistant to chemicals and corrosion. This is important in a marine environment, where fender face panels are exposed to a variety of chemicals and pollutants. The resistance of UHMWPE to chemicals and corrosion helps to maintain the structural integrity of the fender face panel over time, ensuring that it continues to provide reliable protection for vessels.

Featured content:High Tension PC Strand, Low Relaxation, Indented, Coated ...

How to Choose Ssaw Pipes for Your Next Construction Project?

How easy is it to make your own die?

WHY CUSTOM-MADE TABLE AND HOW TO PICK ONE

The Ultimate Guide to Choosing Bespoke Pipe Clamps

Why is Pipe Fittings Supplier Better?

How Does Flange Supplier Work?

One of the key advantages of UHMWPE as a material for marine fender face panels is its low coefficient of friction. This reduces the friction between the vessel and the fender face panel, helping to prevent damage to both. The low coefficient of friction of UHMWPE also makes it easier for vessels to berth and unberth, contributing to the overall efficiency of the berthing process.

In terms of durability, UHMWPE marine fender face panels are known for their long lifespan. The material does not degrade or deteriorate easily, even in harsh marine environments. This means that once installed, UHMWPE marine fender face panels can provide reliable protection for vessels for many years, making them a cost-effective solution for marine infrastructure.

To ensure the durability of UHMWPE marine fender face panels, proper installation and maintenance are key. The panels should be securely fastened to the fender system and regularly inspected for any signs of wear or damage. Any damage should be promptly repaired to prevent further deterioration and ensure the continued effectiveness of the fender face panels in protecting vessels.

In conclusion, UHMWPE is a highly durable material for marine fender face panels. Its ability to absorb impact energy, resist abrasion, chemicals, and corrosion, as well as its low coefficient of friction, make it an ideal choice for protecting vessels in a marine environment. With proper installation and maintenance, UHMWPE marine fender face panels can provide reliable and long-lasting protection for vessels, making them a valuable investment for marine infrastructure.

Click here to get more.

Featured content:Applications and Uses of Geocell in Civil Engineering

Non Woven Geotextile vs. Woven Geotextile: A Comparison

LVL Scaffolding Plank: The Ultimate Solution for Sturdy and Efficient Construction Work

Features and Advantages of Welded Gabion Wire Mesh

Advantages and Disadvantages of PVC Water Supply Pipes

Enhancing Tile Adhesive Performance with HPMC: Key Considerations and Applications

What is the difference between rubber and foam rubber?

98

0

0

All Comments (0)

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments